Our buildings are often long lived things, capable of outlasting the society that produced them. The Egyptian Pyramids are still with us, thousands of years after the civilization that produced them collapsed. The shrine of Ise Jingu is an interesting contrast to this - the buildings there are always young, perpetually renewed by a thousand-year old cultural practice.

The Ise Jingu Grand Shrine sits in the forests of Ise-Shima National Park, in Japan’s Mie Prefecture. Ise Jingu (or simply Jingu) is a Shinto shrine dating back over 2000 years, and is one of the most important and sacred Shinto sites in Japan, standing at the top of all other shrines. More than 1500 rituals are held at Jingu every year, to pray for the Imperial family, a bountiful harvest, and a peaceful world.

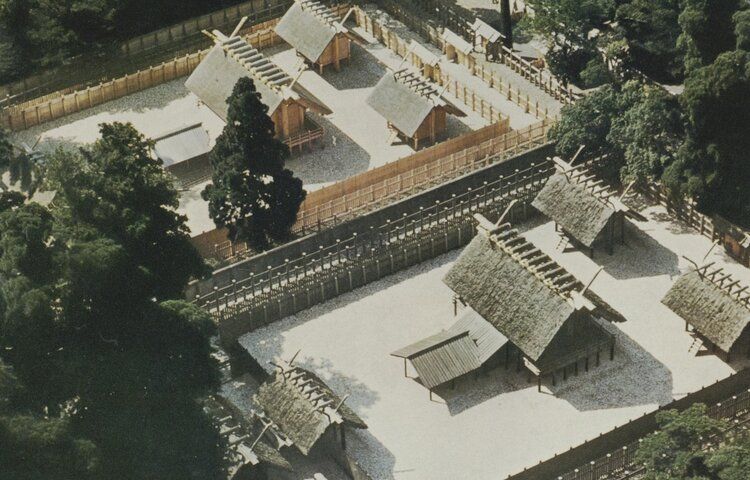

The complex itself is spread over an area the size of Paris and consists of two large shrines, Naiku and Geku, and 123 smaller shrines. Naiku, the inner shrine, is dedicated to the worship of the sun goddess Amaterasu, and Geku, the outer shrine, is dedicated to Toyouke-Ōmikami, the god of agriculture, rice, and industry. Millions of pilgrims and tourists visit Jingu each year, but are strictly prevented from approaching Naiku and Geku, which are hidden behind large fences.

Rebuilding at Jingu

Jingu is famous for its tradition of periodic reconstruction, known as Shikinen sengu, or simply sengu. Every 20 years exact copies of Naiku, Geku, and 14 other shrines are built on empty sites next to the existing structures, after which the old structures are torn down. Altogether 65 buildings, bridges, fences, and other structures are rebuilt this way. This reconstruction at Jingu has taken place every 20 years (with some interruptions) for over 1300 years, since the first sengu took place around 690 AD.

In addition to the shrine structures, the rebuilding also includes creating exact copies of thousands of ceremonial treasures and artifacts, including:

- 60 ceremonial swords

- Ceremonial shields, spears, bows, quivers, and thousands of arrows

- 31 mirrors

- Thousands of yards of silk for curtains, drapes, quilts, bedding, and garments

- Lacquered boxes with silver inlay

- A miniature loom

- A bronzed brazier

All of which are produced using traditional techniques. The rebuilding at Jingu thus means more than simply rebuilding the shrines - it means recreating a sizable fraction of a 7th-century economy.

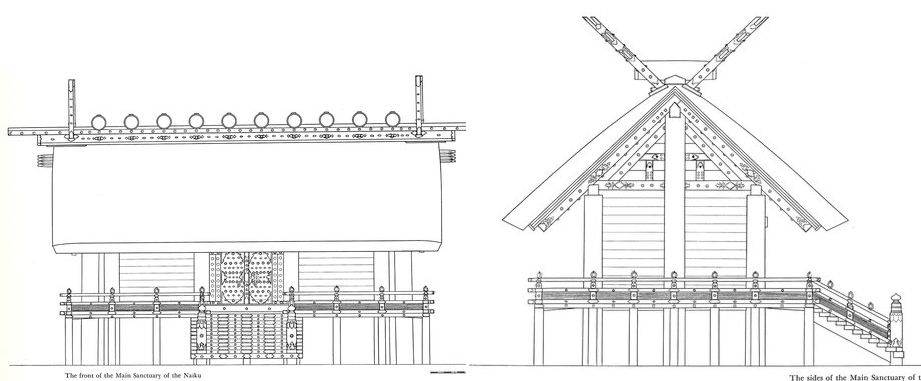

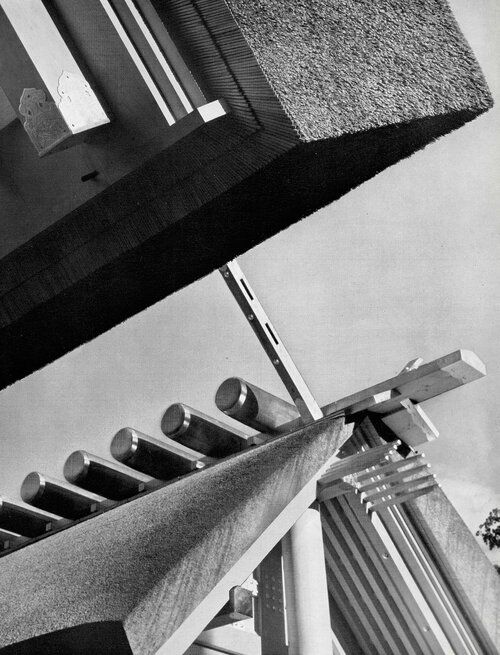

The architecture of the shrines themselves is relatively simple. They consist of large timber logs, embedded into the ground, supporting an elevated post-and-beam frame. The frame is infilled with horizontal timber planks making up the walls and floors, and an elevated veranda surrounds the entire structure. Structures at Jingu are built using hinoki, a Japanese cypress prized for its workability, its golden sheen, and its resistance to decay, and are topped with thatched roofs made of reeds. This architectural style traces its roots to grain storehouses, which were raised off the ground to prevent rice from being damaged by flood and rot.

One part of the construction that isn’t simple is the joints, which consist of carefully carved mortise and tenon connections, along with a small number of iron fasteners. Japan is famous for this sort of wood joinery, and the skill to create them takes years to master.

Jingu’s rebuilding is designed to reproduce the existing structures as exactly as possible. Each rebuilding uses the same materials, the same construction techniques, and is built from the same set of drawings. This level of fidelity presents some unique construction challenges. Obtaining large enough timber posts, for instance, requires trees 300 to 500 years old. Originally these were taken from the forests surrounding Jingu, but supplies ran out in the 11th century; now they must be sourced from all over Japan. And though electric and power tools are allowed for some portions of the process, the work at the shrine itself must all be done using traditional techniques and hand tools. This is at least partially due to the exacting nature of the reproduction - the proper sheen on the planed logs, for instance, can apparently only be achieved via hand planing.

After the new structures are built (and the fidelity of the copy has been confirmed), the previous buildings are then torn down, and any undecayed timber is saved for future rebuilding or repair.

The requirement to use traditional techniques, combined with the number of buildings rebuilt, means that rebuilding Jingu is less of a cultural tradition, and more of a massive industrial effort. The most recent rebuilding required 14,000 cypress timbers, 25,000 sheaves of reeds, took 9 years to complete, and cost over $500 million.

This rebuilding tradition isn’t unique to Jingu - over 30 shrines around Japan have reconstruction traditions that survived into the 20th century. The origins of the tradition are somewhat opaque; some scholars suspect it originated in the practical need to make periodic repairs, while others suggest it was a way to show reverence to the enshrined deity. But one important aspect of the reconstruction process is that it has kept the techniques and technology for building the shrines alive.

Physical and social technology

The building techniques used on Jingu may seem low-tech, but even something as simple as wooden post-and-beam construction sits atop a large pyramid of enabling technologies. The woodwork requires a wide variety of specialized iron tools - axes, adzes, chisels, saws, wedges, planes. Moving the 5000 pound logs into position by hand requires carts, trolleys, tracks, ropes, scaffolding and hoists. Hand-powered drills are used on the reeds to produce the thatched roof. Holes must be excavated to receive the posts. Not to mention the hundreds of yards of silks and textiles that must be produced using traditional looms, weaving, and dyeing techniques, or the hand forging of dozens of ceremonial swords.

But the most important technology at Jingu is social - it’s the transfer of skills and techniques from one generation to the next, ensuring the temples and artifacts can continue to be reproduced accurately. This sort of knowledge is difficult to document - it exists as reflexes and muscle movements that are beyond the reach of language, or as decisions that are so context and environment dependent that it’s infeasible to explain them. The techniques used to build Jingu depend on experience and expertise; learning them requires practice and feedback. Transferring the knowledge required to build the shrines can’t be done with words or text. The only way to pass it on is to create the conditions for someone to acquire it.

The rebuilding process at Jingu is designed to make sure this knowledge transfer occurs. Crews of junior workers are led by a senior carpenter, and the entire construction effort is overseen by a group of senior workers who have participated in multiple sengus. Workers who apply to work on the rebuilding undergo a rigorous selection process, and those selected for one sengu must agree to return for the following one, to ensure an unbroken chain of instruction. Training the younger workers, ensuring the techniques and traditions are passed down from generation to generation, is carried out as faithfully as the rebuilding itself.

Process knowledge and written knowledge

This sort of knowledge is what Dan Wang calls process knowledge - the knowledge of how to do things that can’t easily be written down. A lack of process knowledge is what prevents someone from being a great chef simply by following a recipe.

Jingu’s deliberate effort to preserve process knowledge is rare. While there are many dedicated efforts to preserve written knowledge, far fewer are dedicated to the preservation of process knowledge. We should find this surprising: process knowledge is incredibly valuable, and much easier to lose than written knowledge. It’s not uncommon for written knowledge on a subject to be voluminous, while process knowledge on the same subject is nearly nonexistent. This is why we know the names of every Roman emperor but don’t know how they mixed their concrete, or why we have thousands of pages of Apollo program documents but couldn’t build a Saturn V today.

Process knowledge and institutions

Because much of it can’t be written down or otherwise recorded, keeping process knowledge alive ultimately requires an institution: a stable pattern of social interaction that can persist beyond the life of any single person. An individual carpenter’s knowledge will be lost when the carpenter dies, but a carpenters guild can ensure there’s always a steady stream of new recruits to keep the craft alive.

The more important it is that process knowledge gets retained, the stronger and more capable your institution needs to be - the more it needs to be able to push against changes in the surrounding cultural environment. It’s easy to maintain temple-building techniques when they’re constantly being built all over the country, and the skills are in high demand. It’s much harder when you’re one of the few temples left, and you can’t rely on the surrounding culture to do most of the legwork.

We see this problem with Ise Jingu. Jingu’s rebuilding process ensures carpenters and artisans are trained in the specific techniques Jingu requires, but it assumes the necessary skills will exist in the population for it to draw on - which is increasingly not the case. Though carpenters are still common, thatching and other skills are becoming rare. At one point the weaving skills for producing one of the ceremonial artifacts (a sword bandolier) were possessed only by one weaver with no apprentice. As time goes on, Jingu might need to start training its own artisans for the sengu to continue.

The upside of relying on an institution as your information propagation strategy is that it’s naturally adaptive - the institution can change as the circumstances surrounding it change. Jingu can train its own artisans, if it can marshal the resources - it wouldn’t be the first time Jingu has needed to change its process. In 1585, for instance, drawings of each individual piece of timber were created to aid the rebuilding process. And in the 1920s - 1200 years after the sengu began - a forest preserve was established to ensure a steady supply of necessary timber. As changes have transpired in the language, culture, and technology around Jingu, Jingu has been able to continue replicating its shrines and artifacts by adopting change itself.

Process knowledge and building

We usually think of technology as a sort of ratchet, that once we as a society learn how to do something, we don’t have to worry about it getting un-learned. If losing process knowledge was a real risk, after all, we might expect a long list of “lost” technologies - techniques that we possessed written descriptions of but couldn’t replicate. But the list is fairly short.

But I wonder if the modern world isn’t increasingly susceptible to losing large chunks of it’s process knowledge. Division of labor increases as the market gets larger - a large, globalized market means technology and civilization is increasingly enabled by thousands of tiny niche skills possessed by a small number of people, and by processes that exist in just a few places around the world. The most advanced semiconductors, for instance, are now built by just one firm, as are the EUV machines used to build them (I wonder if there are rules about how many ASML engineers are allowed to fly on the same plane together).

The internet and software is only accelerating this trend: as coordination costs get lower, it becomes easier and easier for companies to use outside services instead of building capabilities internally, concentrating knowledge in fewer and fewer organizations.

We can actually see this happening in extreme cases, such as advanced military technology where the process knowledge is a) not widely known and b) deliberately kept that way. In 2000, a program to extend the service life of W76 nuclear warheads was interrupted when it was realized that a critical material, Fogbank, could no longer be manufactured. Limited documentation had been kept, and everyone who knew how to make it had retired. The DoE ultimately spent 8 years and tens of millions of dollars reverse engineering it’s production process. The SR-71, the fastest plane ever built, was hand-assembled by engineers at Lockheed. Just 32 were made, after which the tooling for them was destroyed, to prevent anyone else from building one. And no one ever did.

The risk of losing process knowledge is real. So perhaps we need more institutions like jingu, dedicated specifically to making sure our process knowledge stays alive, and deeply woven into the fabric of the surrounding culture.