Sometimes I come across a physical thing and realize that I might be able to use it for both pragmatic and political purposes. Recently I bought a spool of mason’s twine at a hardware store. It was a practical purchase, but a few hours later I reused it for rhetorical ends, citing it as an example of a cheap, imported product so that I could make a point about globalization. Being used as an argumentative prop didn’t seem to affect the twine, but a few days later I cut some off and used it to lay out one edge of the deck I’m installing in my backyard. I cut the twine quickly and carelessly, with a pocket knife, and watched as it unraveled a bit. And now, I’d like to use this image — a spool of orange nylon twine, its neat coil disrupted and its cut end frayed — to show how our understanding of technological development unravels over time.

Here’s a bit of received wisdom, which I believe has real explanatory power: Science and technology can seem to pull each other, and humanity, into the future.

This viewpoint is discussed in detail in Managing the Flow of Technology, which was published in 1977 and then recommended to me by the CTO of an oil and gas equipment manufacturer in about 2015. The book was written by Thomas J. Allen, a former Marine who worked as an engineer at Boeing before becoming a professor at MIT’s Sloan School of Management. It is a near-perfect artifact of twentieth-century R&D management theory, optimistically attempting to explain how and why the preceding few decades had brought so much progress to the human (and specifically to the American) experience.

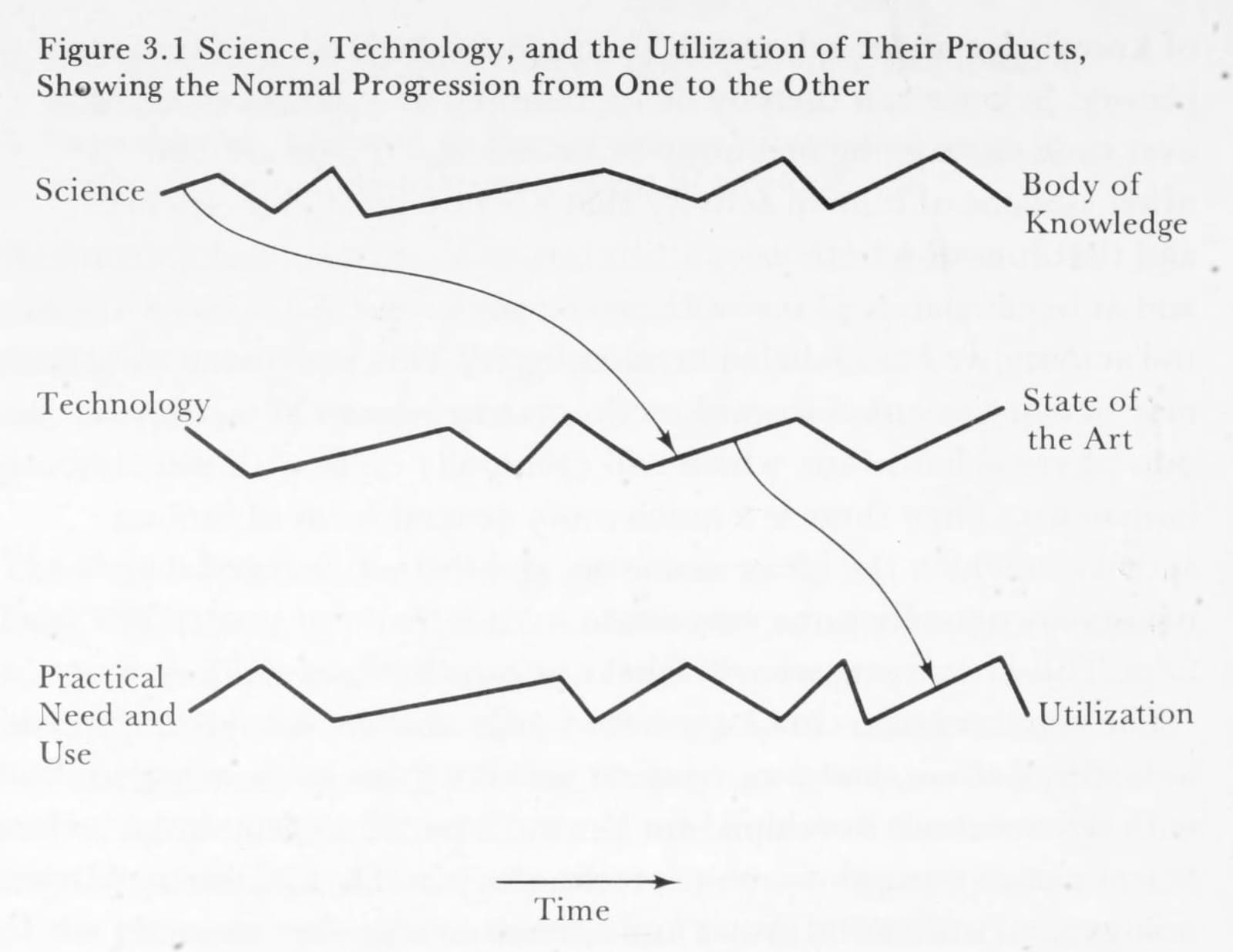

“Both science and technology develop in a cumulative manner,” Allen writes, “with each new advance building upon and being a product of vast quantities of work that have gone before.” Allen describes the communication patterns between private-sector technologists and university research programs as surprisingly sparse, noting that science and technology often progress “quite independently of one another” and referencing one study which concluded that “most advances in the technological state of the art are based on no more recent advances than Ohm’s Law [published in 1827] or Maxwell’s equations [1861-1862].” But he goes on to describe scenarios in which “technology has defined important problems for scientific investigation,” spurring renewed investigation and eventually true understanding.

While Allen doesn’t use the phrase explicitly, he describes what some modern thinkers call the “flywheel effect” between science and technology. “Science enables advanced technology,” a recent commentator claims, “and technological and economic progress then in turn enable scientific progress.”

“But what about the technologies that developed before science,” I think. “What enabled their development, and how did the advent of science affect them?”

Take, for a convenient example, my mason’s twine. Humans have used string and rope like it — twisted or laid cordage, made from natural fibers since time immemorial and from synthetic fibers since World War II — for maybe forty thousand years. This is an order of magnitude longer than we’ve used metal fasteners, or the wheel, or written language. Cordage is older than beer, money, and agriculture, and our earliest examples of ancient rope look similar to my mason’s twine in ways that ancient beer, money, and agriculture do not. Even after modern science emerged, the way we fabricated and used rope didn’t change all that much. Open a textbook on the history of rope, and you’ll find that its first 39,900 years can be distilled down to four pages; the rest of the book all happens after 1930.

How did more or less modern-looking rope develop in a society bereft of science, and why didn’t rope evolve more as humans became dramatically more intellectual? To what extent does it matter whether humans truly understand how their technologies work?

When I think about the problems that my kids are likely to face at some point, I imagine them falling into two rough categories. The first category, and the one that I most hope to prepare them for, consists of obstacles that can only be overcome by adjusting one’s internal outlook. Work, relationships, the weather: These problems aren’t so much about the world as they are about our own expectations, and how we react when they aren’t met.

The other category, and the one that’s more likely to be discussed in essays about either rope or technological progress, involves things that will be overcome — or not — through some combination of science and engineering. I imagine these two fields in more or less constant tension, each one pulling and pushing the other, back and forth over the past few centuries. Engineers attempt to make better ropes, then realize they need a better scientific understanding of, I don’t know, the way braided fibers act under extreme tension. Science steps in, people working in lab coats for decades and eventually, we hope, designing an experiment so brilliant and revealing that true knowledge emerges. Engineers consume this knowledge through published papers and trade associations, and integrate it into whatever they’ve built so far, and the cycle repeats.

I possess a fairly high degree of trust in this model of progress, at least when combined with the self-awareness and mindfulness mentioned previously. But when I look at physical objects in my life, and think about how they’ve developed, I’m often shocked at their circuitous and haphazard stories. As I wrote in On Vulcanization:

When I pause to think about some seemingly simple material — chocolate, silk, reinforced concrete, vulcanized rubber — I’m often struck by the fact that at some point in history, some person or lineage of people spent years, or decades, or centuries figuring out the complex process by which it’s now made. Take chocolate, for example: To go from whole cacao beans to a chocolate bar requires a rather precise sequence of steps. Beans are harvested mostly by hand, then spread on the ground to decompose and ferment. The fermentation process depends on a relatively narrow range of temperatures and humidities, and it is only understood today after huge advances in organic chemistry and microbial biology. The point at which fermentation ends must also be controlled with some precision, the beans being dried just at the right time in order to kill off the naturally-occurring microbes. Then they are graded, hulled, and distributed through a complex and shadowy supply chain to companies that produce the finished product: a delicate material, which has a specific and surprisingly elusive crystalline structure, and which will take on undesirable qualities if its temperature strays from a 4-5 degree Celsius band.

It’s one thing to understand this process as a consumer today, but another to imagine its invention. Chocolate as we know it was invented around 1847, well before X-ray crystallography allowed us to understand the polymorphic crystals that determine its qualities. Early academic research on the chocolate tempering process dates to 1951, but it wasn’t until 1966 that its sixth (and possibly last) form was discovered. And tempering chocolate is still tricky work: even today, highly trained pastry chefs, with millions of followers on YouTube, who work in exquisitely outfitted test kitchens, often struggle to recreate chocolate’s desirable “Form V.” From our vantage point, it makes sense to push through the tempering process, no matter how annoyingly hard it is. We have tasted chocolate, and we know it’s possible to reproduce, and we can rationalize the struggle by imagining chocolate’s flavor and smooth, snappy bite. But the world’s first chocolate was produced by someone who had never seen the stuff, and who could only guess what a world with chocolate would be like.

It feels so unlikely to me, that so much technological progress – on chocolate production, but also on building materials or textiles or rubber – was made speculatively, with only a hunch and a hope about what the outcome might be. If I wanted to improve some complex manufactured product, I’d really want to understand the science at hand. But the people who invented chocolate didn’t start with an understanding of chemistry. They started with a sense of the adjacent possible, and a desire to explore that space.

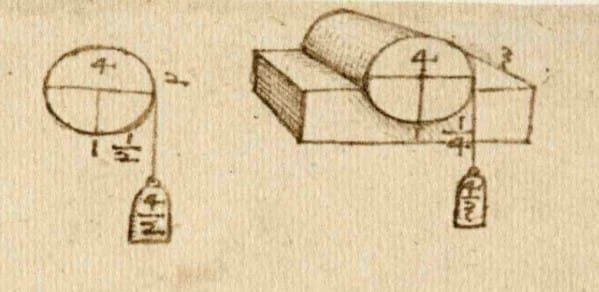

My kid wants to make a pendulum. I suspect its purpose is occult — the kid has a book on spells, and the pendulum is potentially intended to reveal some hidden truths — but I try not to let this throw me off. “Of course we can make a pendulum,” I say. “Sure, let’s do it right now.”

We go downstairs, and I pull the mason’s twine down from its bin. I retrieve the hot knife, and plug it in. The whole time I’m talking, maybe about pendulums or maybe about rope, or hot knives, or the test weights that I think we should use to make a pair of pendulums. The kid doesn’t seem to care about this, one pendulum being sufficient for whatever truths the kid wants to reveal, but I quickly measure out two lengths of mason’s twine and cut them with the hot knife.

This kind of writing — industrial history meets personal reflection — is what Scope of Work does best. Support it with a paid subscription.

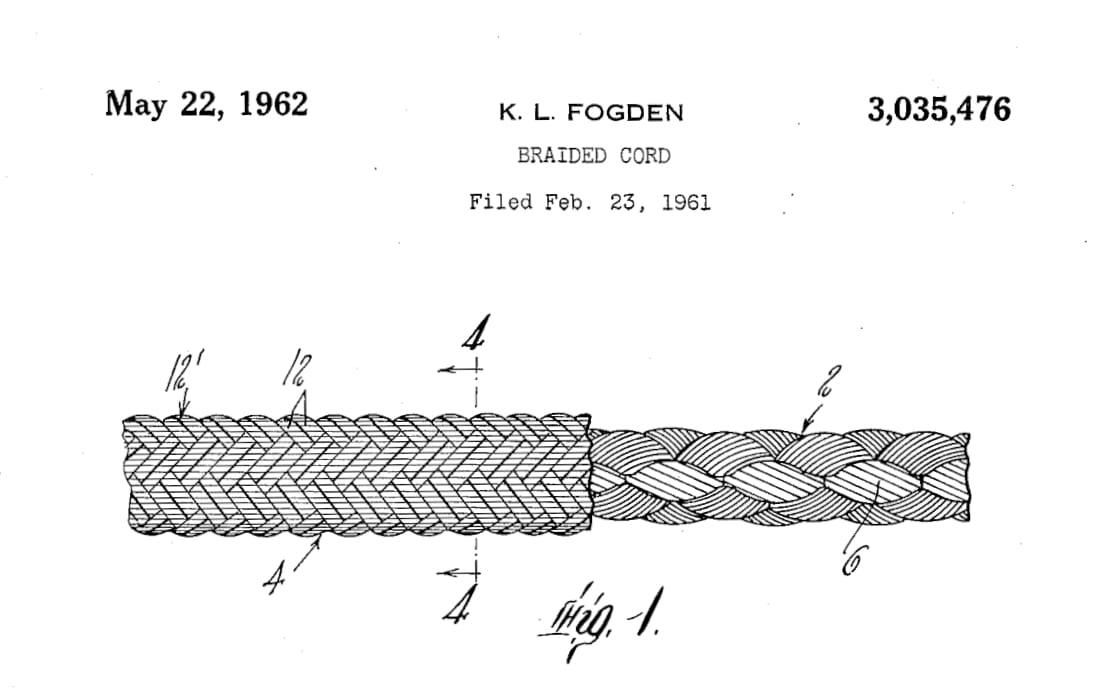

After the pendulums have been made, and after my pendulum lessons have been acknowledged, and after the kid has made another, shorter pendulum with a piece of unknown metal found in the backyard, and after this shorter pendulum has been unceremoniously discarded after it either did or didn’t reveal any hidden truths, I sit down at my desk and cut another piece of twine with a sharp pair of shears. I put the shears down and lay the twine in front of me. I give its cut end a little flick between my fingers, letting its three strands separate a bit. I take a pair of calipers and note the twine’s diameter: about 1.5 millimeters. Each of its three strands is itself made up of dozens of fine filaments. Their diameters: about .03 mm, though I should probably check with a micrometer. I make a lame attempt to count these filaments using a three-step loupe, and determine that there are a lot of them.

I “know,” in a vague sense, that the filaments in my mason’s twine are held together by friction. The twine is, importantly, twisted, and the twisting smushes the filaments against each other, and once they’re smushed together they transfer load to each other so that the twine acts as a single tensile member. This same action is, and has always been, critical to our ability to make long ropes out of short, natural fibers. Once the fibers are twisted together, the friction between them lets you pull on one fiber and transfer load to the rest of the rope.

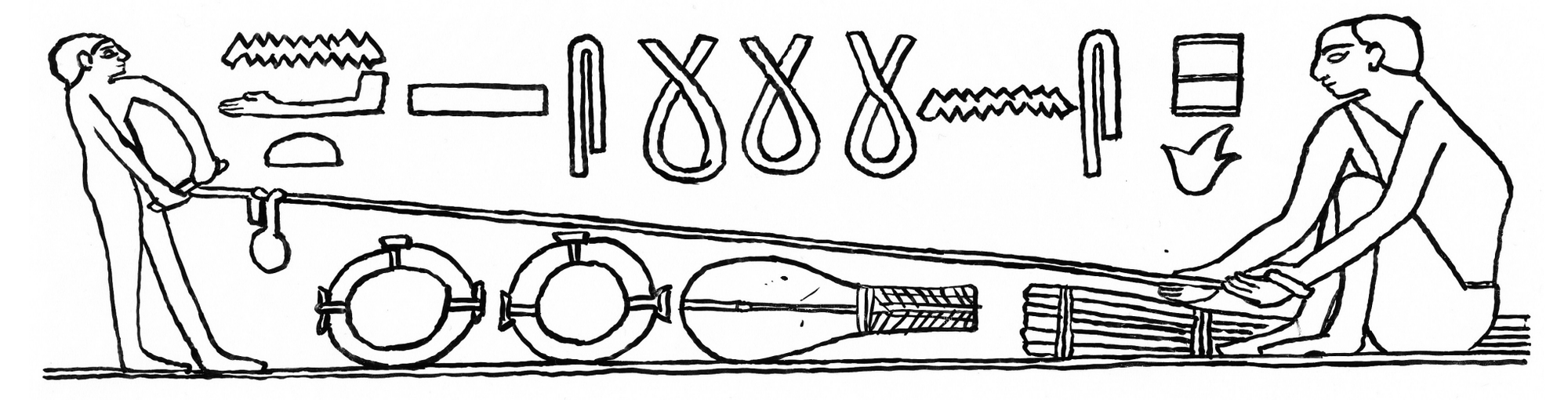

Presumably the people who made my mason’s twine understand this better than I do. Presumably manufacturers of more primitive-looking sisal and hemp ropes understand it too. But for most of recorded history, and a good chunk of human pre-history, we made twine without understanding friction at all. The basic concepts of sliding friction weren’t documented until Leonardo Da Vinci wrote down his findings (but did not share them with anyone) in 1493. It wasn’t until 1699 that someone (the French physicist Guillaume Amontons) published on the topic. This means that for roughly 39,700 years, humans made and used twisted rope without fundamentally understanding one of the core scientific concepts it relies upon. Think of it: Not only was Christopher Columbus wrong about how big around the world was. He didn’t even know how his ships’ halyards, sheets, and dock lines worked.

Christopher Columbus lived before modern science, and didn’t understand how rope works. I live in an era when I don’t really need to understand how rope works: If I’m ever stumped, I can simply look it up on my computer. But I wonder if there was a time between the advent of science, and now, when skilled but unsophisticated mechanics really understood how their rope worked.

I Google “rope-making machine” and end up on a video posted by user “Ozzie’s Oddities.” It’s unclear who’s behind the camera, but I assume the person in front of the camera is Ozzie. To the left of the camera is a woman who is referred to as “Ozzie’s assistant.” Both Ozzie and his assistant appear to be in their seventies. Ozzie wears blue jeans, a blue work shirt, red suspenders, and a large straw hat. He has what he calls an “old time rope maker,” which consists of a half-inch thick piece of wood with three steel hooks stuck through it. Ozzie leans down and opens a white five-gallon bucket on the ground in front of him. In the bucket he finds a rusty clamp (“how’d that get in there...”) and a long spool of light brown twine. He pulls the end of the twine out and ties it to one of the hooks, then loops it between the hooks and a tool, which his assistant holds a few feet away.

Once the twine has been looped back and forth between the hooks and the tool to make six strands, Ozzie grabs a crank and starts twisting the hooks. After a few revolutions, three twisted pairs of twine become visible — but Ozzie keeps twisting. “See how it’s getting? We want to keep going so it gets a fairly good tension,” he tells us. Another minute passes, and “she’s just about ready to go.” Ozzie switches spots with his assistant, then grabs the strands of twine and pulls them off of the back of the tool. They come together in one fluid motion, coiling around each other and seeming to almost relax into a triple helix. Ozzie’s assistant keeps twisting the hooks, and Ozzie slowly pulls the finished-looking rope off of the tool. “It’s very simple — this is the simplest way,” Ozzie tells us. His assistant is stoic, only cracking a smile when Ozzie informs us that “we’re at the end of our rope.” He pulls it off of the rope-making machine and ties an overhand knot in its dead end. “We made a rope today,” he exclaims.

Without really considering the question, I would almost certainly call Ozzie’s rope-making method “unscientific;” the concepts it relies on are certainly older than Maxwell’s Equations. But if I thought about it a bit, I’d probably start asking myself: What even is science?

Presumably things that follow the scientific method can be called “science.” Maybe a scientist is someone who looks at the world, makes observations, proposes a falsifiable hypothesis, and then performs some manner of experiment, or statistical analysis, which can then be used to either discard or tentatively accept the hypothesis. A scientist might wear white and work in a corporate lab; they might use pipettes all day; they might pre-register their hypotheses and worry about the replication crisis. The key, in this definition, is that scientists use the scientific method — a set of rhetorical tools that humans have used to develop knowledge for the past couple hundred years.

I think that Wallace Carothers was a scientist. Here’s a picture of him, dressed in a three-piece suit and standing next to some lab equipment. Presumably the picture was taken in the early 1930s in the Du Pont lab in Wilmington, Delaware, where he worked after his doctorate and before his self-inflicted death by potassium cyanide. According to a promotional pamphlet published by Du Pont in 1988, the program that Carothers was involved in “was indeed fundamental and pure research,” costing $27 million and leading to “prophetic” findings. The first of these was Neoprene, whose discovery, in 1930, temporarily surpassed German research on synthetic rubber. But Carothers focused mainly on fibers, studying how polymers formed and how they might be manipulated into usable formats. According to a 1959 review of the economics of invention:

The research was in a new field of chemistry, and Du Pont believed that any new chemical breakthrough would likely be of value to the company. The very lack of a specific objective, the flexibility of the research project, was an important factor contributing to its success. In the course of research Carothers obtained some superpolymers that became viscous solids at high temperatures, and the observation was made that filaments could be obtained from these materials if a rod were dipped in the molten polymer and then withdrawn. At this discovery the focus of the project shifted to these filaments. Nylon was the result, but at the start of the project Carothers had no idea, nor could he possibly have known in advance, that his research would lead him to the development of a new fiber.

One of the benefits of doing research about scientists is that it is in their nature to leave a paper trail. This makes it easy to string together a series of historical snapshots, helping your readers really understand how a complex set of events must have played out. Carothers’ lab first produced nylon in 1935, a year during which his personal life had already begun to unravel. He was earning a good income and had bought a house, which he moved into, as a thirty-seven-year-old bachelor, with his parents. The situation became tense: Carothers was dating a married woman at the time, and his parents disapproved, and Carothers, who had already written to friends about “neurotic spells” and “complete lack of feeling,” began carrying a cyanide capsule on his watch chain. In 1934, he failed to show up at work and was eventually discovered in a psychiatric clinic. In 1936 he was again institutionalized, then permitted to leave for a two-week hiking trip in the Alps. When the two weeks were up, his hiking companions returned home — but Carothers remained, apparently without informing his wife. His formal work obligations were terminated shortly thereafter, and within a year he was dead. His first and only daughter, Jane, was born six months later. Nylon was first used in twisted rope when she was about ten, and she would have been in her late teens when kernmantle and double-braided synthetic cords were developed — both big technological advancements. Rope had looked more or less the same for forty thousand years of human history, but before Jane Carothers could legally drink alcohol a revolution in rope-making technology had occurred.

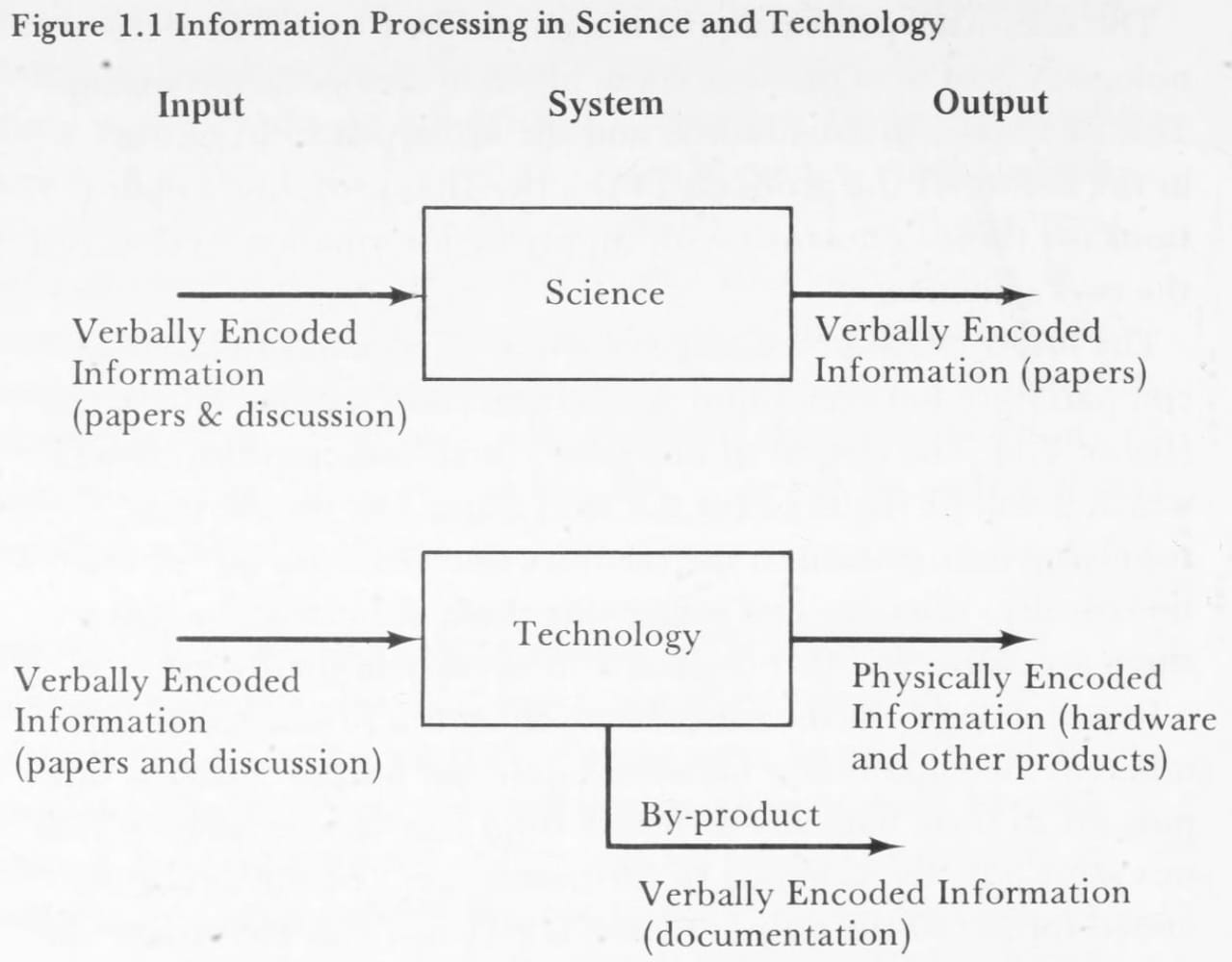

In Managing the Flow of Technology, Allen proposes that we can see science and engineering as having the same basic input: verbally encoded information. Science and engineering both start with verbally encoded information.

Engineers consume verbally encoded information, whether in the form of written documents, or word of mouth, or whispers from god, and from it they weave together something physical. They also, in the course of things, produce new verbally encoded information: They gossip with colleagues, and write product documentation, but their primary output is something physical.

Scientists, on the other hand, focus basically all of their efforts on producing more verbally encoded information, with no other strings attached. They consume knowledge, and then do some stuff, and at the end of the day they write down everything they know and hope that it’s greater than what they started with. Science is a machine that ingests verbally encoded information, and adds to it.

Sometimes, science is performed through experiments, but experiments are neither necessary nor sufficient for science. Make a set of pendulums, and tell your kid that you want to run an experiment to show that a pendulum’s mass has no effect on its period. Tie two different weights to the ends of your two strings, and hang the strings from a pair of hooks in your ceiling, and pull both the strings back the same distance before letting them go. They will swing, within some margin of error, in perfect unison. For argument’s sake, let’s say your kid even follows your experimental thread, and the lesson sinks in. This is great, and you both deserve high fives, but it’s not science unless your results are encoded verbally and entered into the corpus of human knowledge.

I think back on all the progress that must have been made during our first 39,700 years with rope. If anyone wrote down what they knew about cordage back then, almost none of these writings have survived. Rope as a technology existed, and we can find physical evidence of its evolution over time. But when we look back into ancient history to understand its evolution better, we quickly lose the thread.

As defined in a 2019 essay by Patrick Collison and Tyler Cowen, progress is “the combination of economic, technological, scientific, cultural, and organizational advancement that has transformed our lives and raised standards of living over the past couple of centuries.” “It’s worth noting that we still need a lot of progress,” the authors write. “Our point, quite simply, is that this process has yet to reach a natural end, and that a more focused, explicit study of progress itself should be one of the next steps.”

Collison and Cowen argue — convincingly, I think — that we should make a serious attempt to understand which efforts and investments have resulted in progress in the past. If Wallace Carothers’ “fundamental and pure research” resulted in progress (stronger, more durable ropes reduce the loss of life and property; cheaper, more plentiful rope lets people reallocate time and money to other pursuits) then we should try to understand, and to the extent possible replicate, the conditions that enabled his prophetic discoveries.

But we should keep in mind that Collison and Cowen are specifically interested in the progress that occurred in the past couple of centuries, and that progress studies as a discipline depends on well-documented historical records. This makes their focus on science appropriate: The past couple of centuries are, partly because of the scientific revolution, documented in ways that allow us to study them. The advent of science means that there’s a whole class of people whose main job is to encode their knowledge verbally, and get it published somewhere. As a result, we can look back and trace the technological warp that runs from Wallace Carothers’ work in the 1930s to the mason’s line I bought a few weeks ago. We know the actual names of the people who worked in this historical macramé. We can read their patent applications and see the earlier inventions that they were building on; we can find interviews with their bosses, explaining how and why they obtained their funding and what their expected outcomes were.

The scientific progress that Wallace Carothers produced did generate a flywheel effect with technological progress. And because the whole thing was done with a mandate of producing verbally encoded information, we can sit here today and understand the conditions that enabled it — and try to replicate them. But if we look back to the people who improved rope technology a century (or a millennium) earlier, the stories we’re able to tell about them tend to unravel.

There are many ways to understand our relationship with rope, many stories we can tell about its development. Progress is one of them. I can look at my mason’s twine through the lens of progress and find a compelling, if tragic, story of its twentieth-century development. I can make a pendulum for my kid and know that the lesson I attempt to convey in the process is one which humans have grappled with for at least four hundred years. Or I can simply tie an overhand knot in the end of a piece of hastily-cut twine — an act of technological preservation that might well have been performed by Neanderthals. When we view them at a broad enough time scale, each of these stories unravels in its own way, never quite managing to splice itself onto its predecessor. It’s up to us, as both storytellers and audience, to decide how we’ll weave their lessons together.

🙏 If this essay taught you something, or helped you see something differently, consider becoming a paid subscriber. It helps me write more pieces like this.