When I pause to think about some seemingly simple material – chocolate, silk, reinforced concrete, vulcanized rubber – I’m often struck by the fact that at some point in history, some person or lineage of people spent years, or decades, or centuries figuring out the complex process by which it’s now made. Take chocolate, for example: To go from whole cacao beans to a chocolate bar requires a rather precise sequence of steps. Beans are harvested mostly by hand, then spread on the ground to decompose and ferment. The fermentation process depends on a relatively narrow range of temperatures and humidities, and it is only understood today after huge advances in organic chemistry and microbial biology. The point at which fermentation ends must also be controlled with some precision, the beans being dried just at the right time in order to kill off the naturally-occurring microbes. Then they are graded, hulled, and distributed through a complex and shadowy supply chain to companies that produce the finished product: a delicate material, which has a specific and surprisingly elusive crystalline structure, and which will take on undesirable qualities if its temperature strays from a 4-5 degree Celsius band.

It’s one thing to understand this process as a consumer today, but another to imagine its invention. Chocolate as we know it was invented around 1847, well before X-ray crystallography allowed us to understand the polymorphic crystals that determine its qualities. Early academic research on the chocolate tempering process dates to 1951, but it wasn’t until 1966 that its sixth (and possibly last) form was discovered. And tempering chocolate is still tricky work: even today, highly trained pastry chefs, with millions of followers on YouTube, who work in exquisitely outfitted test kitchens, often struggle to recreate chocolate’s desirable “Form V.” From our vantage point, it makes sense to push through the tempering process, no matter how annoyingly hard it is. We have tasted chocolate, and we know it’s possible to reproduce, and we can rationalize the struggle by imagining chocolate’s flavor and smooth, snappy bite. But the world’s first chocolate was produced by someone who had never seen the stuff, and who could only guess what a world with chocolate would be like.

It feels so unlikely to me, that so much technological progress – on chocolate production, but also on building materials or textiles or rubber – was made speculatively, with only a hunch and a hope about what the outcome might be. If I wanted to improve some complex manufactured product, I’d really want to understand the science at hand. But the people who invented chocolate didn’t start with an understanding of chemistry. They started with a sense of the adjacent possible, and a desire to explore that space.

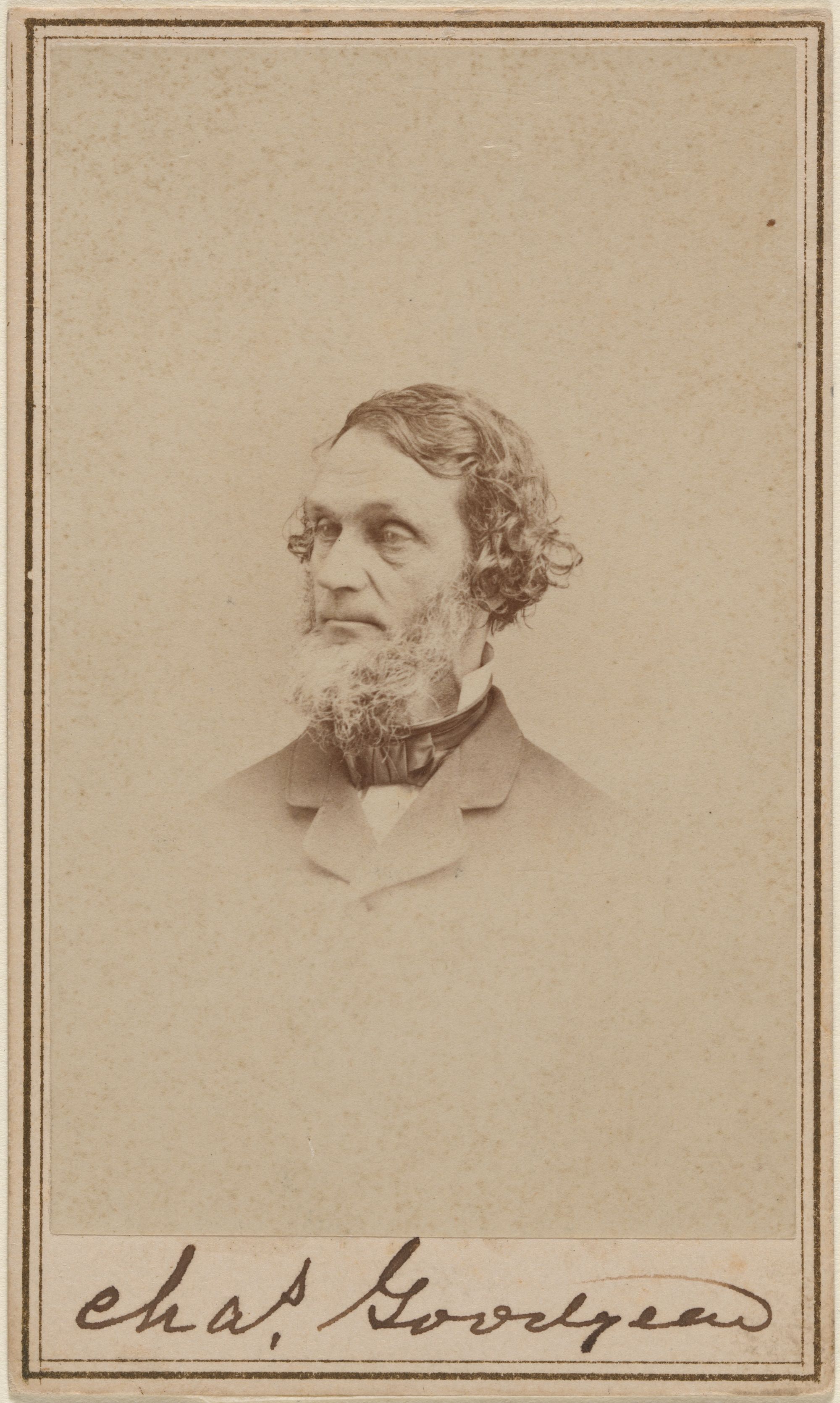

The same is very much the case with rubber. Here our hero – if we might call him that – was Charles Goodyear, a compulsive entrepreneur whose desire to overcome rubber’s shortcomings was matched only by his willingness to bankrupt his family in the process. Goodyear was born in 1800 in New Haven, Connecticut, in an era when New England was the center of American industry. In the sense that his work focused on creating chemical reactions, Goodyear was a chemist. But by education he was simply a hustler, someone who began working at a hardware importer when he was seventeen and who then leveraged his intense curiosity – and all lines of credit available to him – in pursuit of a stretchy, resilient, and air-tight goal.

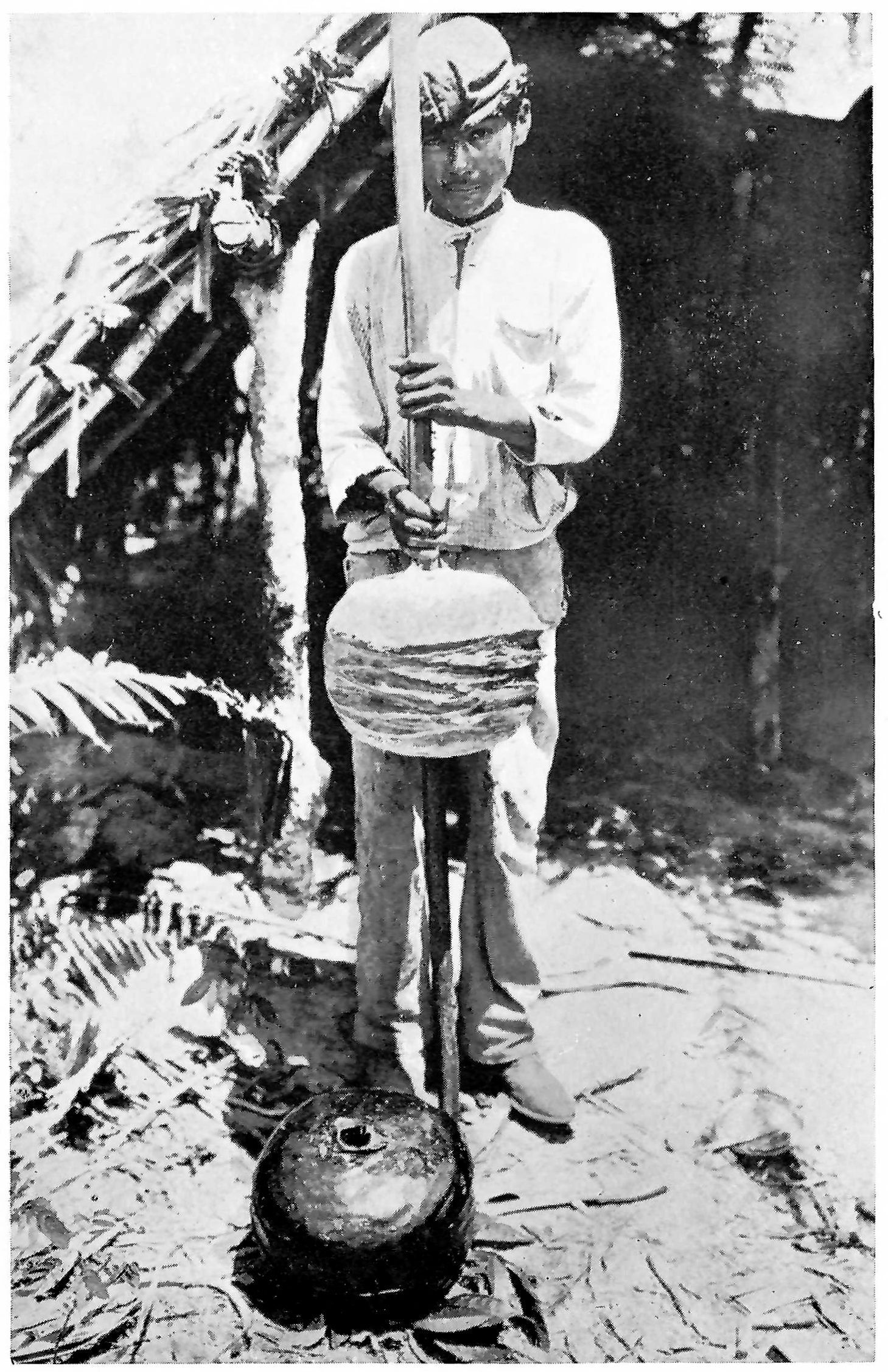

As I wrote last week, the rubber trade was surprisingly active in the first decades of the nineteenth century, with a messed-up Brazilian supply chain providing raw material and frantic entrepreneurs in the US and Europe converting it into finished goods. Liquid latex was tapped by seringueiros in the Amazon basin, who then smoked it to form “fine hard para” balls. These would be floated downstream to Manaus (at the headwaters of the Amazon River) and Para (at the Amazon’s delta), where merchants would sell them on to buyers overseas. By 1830, fine hard para imports to the United States were around 156,000 kilograms (174 US tons), with prices low enough that a more or less destitute Goodyear could afford some to experiment on.

But early attempts to commercialize rubber products were almost always disappointing, and often disgusting. While fresh liquid latex is reasonably inoffensive, it is nonetheless a plant product and will eventually rot, producing an odor that has been described as “strongly fishy” and “very unpleasant.” Raw rubber softens in hot weather and cracks in the cold. Mash two pieces together and they will eventually fuse into one; put a piece under tension and it will stretch out to comic proportions. These qualities, combined with the fact that early rubber products were often sold by vendors who either didn’t know better or didn’t care, meant that they would often degrade rapidly after purchase. Often they would develop an unbearable stench the first summer after they were made, their surfaces turning from glossy to dull and their folds fusing into a solid lump. Rain jackets would be unwearable; life preservers would cease to hold air, and everything would smell “pungent and sickly sweet.”

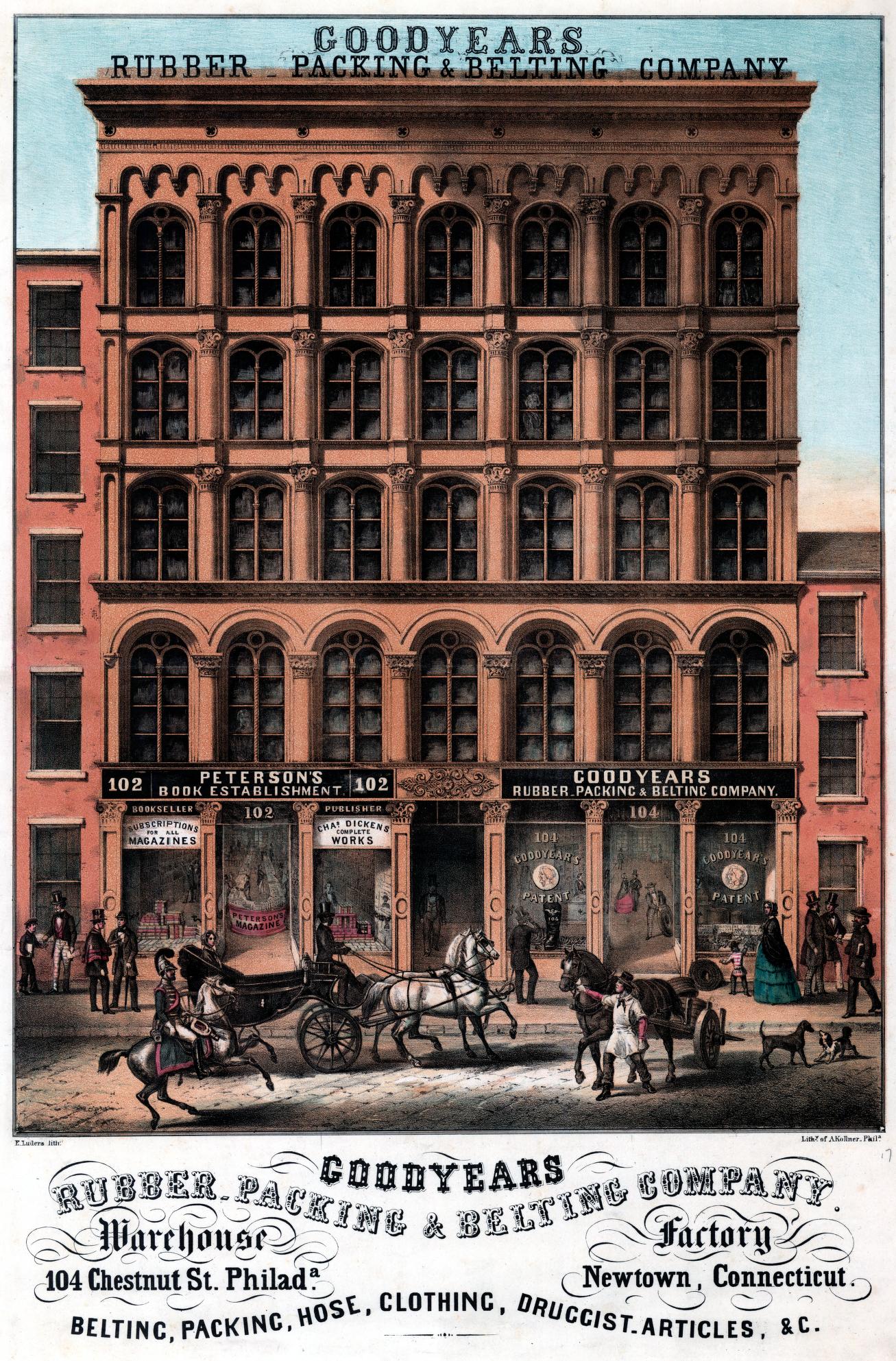

You might imagine Goodyear as an inventor in the mold of Thomas Edison, and in some ways that assessment would be correct. Indeed, it’s difficult to imagine the electrical age without Goodyear’s work, which was critical to the insulated wiring that powered much of twentieth-century life. Both men seem to have been convinced that they were working towards a transformative goal, and both found ways to continue working in the face of setbacks. But where Edison understood his commercial and financial context – and was incredibly adept at raising capital, managing a large research & development organization, and marketing his inventions – Goodyear seems to have been clueless. To wit, perhaps the most remarkable fact about Charles Goodyear is that he bore no relation to The Goodyear Tire Company – which was named after him, by people he had never met, four decades after he died. As Howard and Ralph Wolf wrote in 1936, Goodyear was:

...a man who starved and suffered; who made his experiments alternately in jail cell and sickbed; who was forced to sell his children's schoolbooks to buy food; who was an unwilling intimate of pawnbrokers as well as well as jailers; who was derided and scoffed at and considered demented until he made his great discovery; who thereafter was victimized by sharp bargainers and pickpockets and spent his last years still debt-ridden and shattered in health.

Charles Goodyear seems to have encountered rubber for the first time in 1834, when he was thirty-four and had already outlived two of his children. His first business venture, a hardware store in Philadelphia, had collapsed in 1831, putting him in debtors’ prison – an experience that he described as having given him “a moment to look upon the darkest side of life’s fleeting shade.” His intuition was, as biographer Charles Slack would later write, “to invent his way out of poverty.”

At first, he tried his hand at making hardware and kitchen utensils, but after seeing rubber life preservers at a shop in Manhattan, he spent weeks developing an improved valve for them. But when he attempted to sell his design to the manufacturer, he was ushered into their storeroom – where loads of misshapen, rancid, and non-functional life preservers were kept. “Forget your valve,” the agent told him. “The one invention that could save the rubber industry and earn a fortune for the inventor would be a method for preventing rubber from… this.” In its raw state, rubber wasn’t suited for much of anything – and the speculative industry that had been built up around it was collapsing. As R.W. Lunn would write in History of the Rubber Industry in 1952:

The early history of the rubber industry in America had followed a course which is fairly common in the development of any new industry. All the possible troubles were discounted or ignored and the advantages were recognised and emphasised. When the troubles came and accumulated without signs of ceasing the optimism swung over to despair.

But Goodyear – who had no particular expertise in materials science, nor any store of cash waiting to be put towards a big R&D project – “distinguished himself by recognising and stating the problem, by working for its solution under conditions of extraordinary sacrifice and finally by arriving at a true solution to it.” After his first contact with rubber life preservers, he returned to Philadelphia. A short time later he was again sent to debtors’ prison, bringing with him a bit of rubber and a rolling pin with which to break it down. Goodyear had glimpsed rubber’s adjacent possible, and became obsessed with the idea of what it might become. From then more or less until his death in 1860, he would attempt to achieve some kind of success in the rubber industry.

Charles Goodyear was irresponsible; he was disorganized and messy. He worked for years with rather nasty chemicals and solvents, often in his family’s kitchen and (obviously) without a single rubber glove around. He repeatedly defaulted on his loans, going for broke on some new rubber recipe that would then fail catastrophically when the summer came. He was itinerant, moving from town to town and business venture to business venture, always seemingly convinced that the next one would bring him his inevitable glory.

But while he did very little to record the event, Goodyear eventually came upon a method of improving rubber’s qualities. Over the years he had seen some superficial benefits from adding sulfur to rubber, and eventually – probably by accident – a piece of his sulfur-treated rubber came into contact with heat. Goodyear called the result “metallic gum-elastic,” an analogy to the way in which ore is smelted into iron, but it would become famous as vulcanized rubber: a solid, durable material with stable, predictable properties. Of course, Goodyear didn’t understand the molecular interactions at hand. It wouldn’t be until 1920 that Hermann Staudinger would propose a general theory of how polymer macromolecules work, and our precise understanding of how sulfur creates cross-links during the vulcanization process wasn’t developed until the 1940s. Nevertheless, Goodyear’s intuition had been validated: It was possible to overcome rubber’s limitations.

And so he would spend the next two years reverse engineering his own lucky process, and another decade or so fumbling through various lawsuits and failed business ventures. The trials he endured in the 1830s were never rewarded with riches, and he was left without much more than bragging rights. But in the end he seems to have considered his career a success. He had seen the adjacent possible, and somehow managed to will it into existence – and with it would come all of the flexible, stretchy, and well-sealed possibilities that would define the twentieth century.

I would like to think of Goodyear as the proverbial dog who caught the car, and was then at a loss for what to do with it. But Goodyear was full of ideas about the adjacent possibilities that vulcanization unlocked; he wrote an entire book dedicated to its uses, from “incompressible globes” to bedspreads to flower pots. Perhaps instead he is better seen as one of infinite monkeys, hacking away at a typewriter and eventually producing Hamlet: Disorganized, and probably a little lucky, but responsible for a huge accomplishment nonetheless.

I’ll be back soon with more on rubber’s history: There are some other captivating bits of early rubber processing technology that I'd like to explore, after which I'll shift to the geopolitical forces that moved supply chains from Brazil to Southeast Asia, Africa, and eventually Poland. Thanks as always to Scope of Work’s Supporters and Members (who can look forward to a few off-kilter rubber threads in the Members' Slack this week) for making this newsletter possible. I also relied on a number of texts for this (and last week’s) newsletters, the most notable of which are:

- Noble Obsession: Charles Goodyear, Thomas Hancock, and the Race to Unlock the Greatest Industrial Secret of the Nineteenth Century. Charles Slack, 2002.

- Rubber: A Story of Glory and Greed. Howard and Ralph Wolf, 1936.

- History of the Rubber Industry, Compiled under the auspices of the Institution of the Rubber Industry. P. Schidrowitz & T.R. Dawson, editors, 1952.

Love, Spencer

p.s. - We care about inclusivity. Here’s what we’re doing about it.