About a year ago I got rid of my bike’s inner tubes. In retrospect, it was only a matter of time before I did so: Tubeless tires had gotten a lot more popular since I quit the bike industry, and eventually I was bound to realize that they were popular for good reason. But at the time I wasn’t consciously looking for an epiphany: I simply wanted to run some lightweight, “supple” tires in an effort to make my bike a bit more comfortable to ride. And then came an onslaught of flats. The new tires were quite thin, and could be easily punctured by the fine layer of crushed glass that seems to cover New York City’s streets. And once a piece of glass got through the tire casing, it would immediately puncture my inner tubes.

Whereas automobile tires are designed with thick treads that resist being punctured, bike tires – like basically everything else on a bike – tend to be as thin and light as possible. For many decades, bike tires weren’t designed to be airtight either: A bike’s rim, spokes, and hub provide structure, the tire provides traction and some durability, and the inner tube – a torus, typically made from butyl rubber, which is slipped inside the tire – keeps pressurized air inside.

This all changed in 2001, when Stan Koziatek, an amateur mountain biker and go-kart track designer, patented “a system and method for retrofitting non-tubeless tires” that relied on liquid sealant made of latex, ammonia, and water. Within a few years, the brand he created (the eponymous and highly descriptive Stan’s NoTubes) had become a staple in serious bike shops, prompting first mountain bikers and then basically every other committed cyclist to consider throwing away their inner tubes.

At first, the process was a little hacky; very few rim or tire manufacturers would officially sanction it, and Stan’s sold retrofit kits to take your existing gear and make it work with tubeless sealant. But over time the benefits of running tubeless – fewer flat tires, reduced weight, lower rolling resistance, and the ability to run your tires at shockingly low air pressures – overcame the industry. Today, most mid- to high-end bike companies at least implicitly support tubeless tires, and virtually every large tire brand offers tubeless options. And it doesn’t stop with bikes: today, Stan’s NoTubes markets their latex-based sealant to golf carts, tractors, wheelbarrows, and hand trucks.

All because of latex.

Latex is everywhere. It’s in condoms and gloves and water balloons; it’s in mattresses; it’s in a wide range of waterproof and water-resistant coatings and countless industrial products. Latex is the key ingredient to natural rubber, and any machine that doesn't contain natural rubber will often contain some form of synthetic rubber – a class of materials that are inextricably linked with the early-twentieth-century latex industry, and the engineering opportunities (and geopolitical challenges) it spurred.

Natural latex – the same milky white liquid that I squirt into my bike tires every few months – is produced by roughly 10% of the plants on Earth. It is distinct from sap, excreted by a plant’s laticiferous system and believed to provide defense against insects. Next time you see a dandelion in a patch of grass, pick the flower and look at the straw-shaped stem. In a few moments, a milky liquid will appear on its cut edge; that’s latex. If you were to collect that liquid and let it dry out over a fire, or mix it with an acid, then it would coagulate into natural rubber.

Throughout history, many attempts have been made to produce latex from all kinds of plants, with disappointing results. Thomas Edison alone is said to have tried latex extraction from over 17,000 species. But only one plant produces enough latex for industrial-scale rubber production: Hevea brasiliensis, the Brazilian rubber tree, which was the engine behind the Brazilian rubber boom from 1879 to 1912 (and supplied virtually all of the rubber made before 1945). Native mostly to the Amazon basin, latex from hevea was used for a variety of recreational, practical, and religious purposes in pre-Columbian Mesoamerica. The first European accounts of rubber date to about 1500, and for a few centuries it was frequently a hot (if poorly understood) commodity.

Imagine, for a moment, that you’re living in New York City in the mid-1800s. You might be familiar with both the automobile and the bicycle, but the former is a rarity and the latter is referred to colloquially as a “boneshaker,” for the extreme discomfort the rider experiences while bumping along atop its solid, uncushioned wheels. Your shoes are made of leather and lack cushioning of any kind. You may know of water-resistant oilcloth, but the idea of a “waterproof” rain jacket is mostly theoretical. “Elasticity” is also an abstract concept, limited to springs and other industrial applications. You might be aware of electricity, but other than rubber’s close cousin, the more rigid gutta-percha, reliable wire insulation is almost nonexistent – so any electrical wire you’ve seen has been uninsulated and therefore not something you want to come in contact with. Sealing anything – a mason jar, a pressure cooker, a hose coupling – is expensive and often unreliable. All of your material possessions – and probably everything you have ever touched – are either rigid (like wood, metal, and ceramics) or completely soft and pliable (like textiles and leather).

The world before rubber came into its prime – which is to say, the world before about 1900 – was inflexible, slippery, and poorly cushioned. So even though rubber’s quality varied widely in the 1800s, and it had almost no practical applications, and it would crack in the cold and turn into goo in the heat, its properties still led people to be totally enchanted with it.

Wild rubber trees grow about 400 meters apart, and the Brazilian rubber boom relied exclusively on wild rubber trees. At its peak in 1912, roughly 190,000 people were engaged (either by choice or by de facto enslavement) in the Amazonian rubber trade. The vast majority of them would be classified as seringueiros – independent rubber tappers who lived and collected latex in the remote jungle, so called for the local name for the rubber trees: seringa. Seringueiros would be contracted by a single patrão or patron seringueiro, who acted as both a broker for the rubber they produced and as a loan shark for everything they needed to do so. As E.C. Buley wrote in North Brazil in 1913:

The patron himself is usually financed by the large rubber houses of Belém or Manaus, and, in his turn, finances each of his “seringueiros,” of whom he may control 200 or 300. He supplies them, at exorbitant prices, with all the stores they require for their stay in the rubber forest, which extends usually from May to October. Thus each “seringueiro” starts the season heavily in debt to his patron, and, it often happens, returns from the forest without having extinguished that debt.

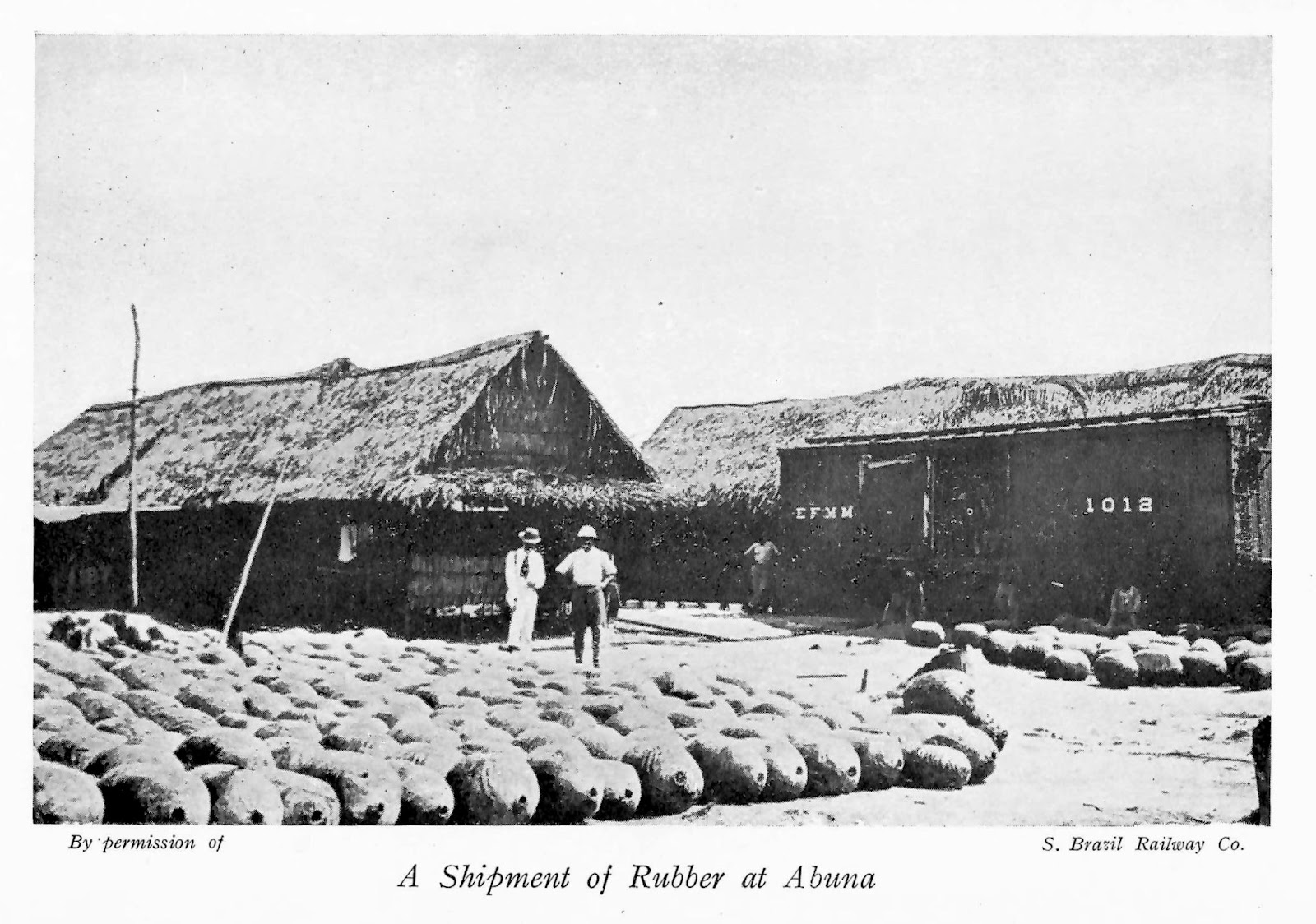

Day after day a seringueiro would collect latex, returning to a small hut each afternoon to coagulate the liquid in the “heavy acrid smoke” of a fire made of palm nuts. The result – a ball of natural rubber, weighing up to 20 kg, would eventually be floated down the river to Manaus to be sold.

It was a brutal lifestyle, and full of irony – not the least of which was its utter dependence on imported goods. Everything that was used by the rubber trade was imported. Machetes were imported to clear the forest, and then wood was imported – shipped across the ocean and up the Amazon River to the middle of the rainforest – to construct buildings. As John Tulley wrote in The Devil’s Milk:

The staples of life for the laboring poor were rice from Rangoon via Liverpool and beans from Argentina, supplemented with imported tinned fish and fruit, all imported at vastly inflated prices despite the bounty of nearby tropical forests and rivers teeming with fish and fruit. Farinha, the staple bread substitute of the poor, was imported from Marahao…Only after the end of the rubber boom was there any attempt to broaden the local industrial base, a program of import substitution made necessary because the population could no longer afford to buy imported goods.

To say that the Amazonian rubber industry was inefficient would be to miss the point, though; the industry’s deep-seated immorality was its most notable trait. The Brazilian rubber boom occurred after about three and a half centuries of absolutely brutal conditions in South America, and it replicated the same systems of repression, enslavement, and exploitation that Portuguese and Spanish settlers had implemented in the 1500s. Rubber tappers were almost always coerced in some way. They lived in incredibly dangerous environments, and were denied the cultural, economic, and technological capabilities to improve their situation. While living in malaria-infested forests that frequently had rich supplies of Cinchona plants, seringueiros often lacked access to quinine – the only effective malaria treatment at the time, which was extracted from Cinchona bark. One contemporary observer estimated that seringueiros had a shocking 33% annual mortality rate. In 1912 Sir Roger Casement, a British diplomat, presented a report to the House of Commons on the Putumayo Genocide, which had been perpetrated by The Peruvian Amazon Rubber Company. The company operated along the Putumayo River, which flows directly to Manaus, in the last decade of the Brazilian rubber boom. In the process of extracting 4,000 metric tons of rubber, they also enslaved tens of thousands of Indians and killed at least 30,000. Casement calculated that for every ton of rubber the company produced, seven people died.

The incredible thing to me is that the Brazilian rubber boom occurred almost entirely before the Model T’s ascendancy. The pneumatic tire – rubber’s killer use case – wasn’t even developed until 1888, fifteen years after nearby Colombian rubber exports peaked in 1873. At a more foundational level, the rubber vulcanization process – a critical piece of technology, without which most rubber products would only last a few months – wasn’t invented until 1839. And yet the rubber trade was bustling, even in the first decades of that century. As Charles Slack wrote:

The American obsession with rubber during the early 1830s bears a striking resemblance to the Internet frenzy of the 1990s. In each instance a new industry emerged, one so promising and so unlike any before it that investors and entrepreneurs alike willingly blinded themselves to pitfalls, even ones that in retrospect seem obvious. Just as speculators drove the value of untested, unprofitable dot com start-up companies to surreal levels during the 1990s, thousands of nineteenth-century New Englanders poured their savings into the miracle substance called rubber without knowing much of anything about it. In both cases, the education was hard-earned and painful.

In hindsight, those investments bore some wisdom, though almost nobody involved in the Brazilian rubber boom would realize the returns. And for all the atrocities committed in the Amazon up until 1912, it would take three key factors – vulcanization, the pneumatic tire, and the Model T – to ensure rubber’s place in the pantheon of 20th-century materials.

Next week I'll be writing about Charles Goodyear, and the decade's worth of haphazard process development – and financial ruin – that led to his eventual breakthrough. This week’s issue relied on many sources, the most notable being:

- Crude Rubber and Compounding Ingredients. Henry C. Pearson, 1909.

- The Devil’s Milk: A Social History of Rubber. John Tully, 2011

- North Brazil: Physical Features, Natural Resources, Means of Communication, Manufactures and Industrial Development. EC Buley, 1914.

- Noble Obsession: Charles Goodyear, Thomas Hancock, and the Race to Unlock the Greatest Industrial Secret of the Nineteenth Century. Charles Slack, 2002.

- From Silver to Cocaine: Latin American Commodity Chains and the Building of the World Economy, 1500-2000. Zephyr Frank, Aldo Musacchio et al, 2006.

Love, Spencer

p.s. - We care about inclusivity. Here’s what we’re doing about it.