Here’s a surprisingly compelling corner of the engineered world: Nineteenth-century apple parers.

Sometimes my kids request that an apple be peeled, and if time and energy allows then I’ll reach for a general-purpose kitchen tool (a vegetable peeler, a paring knife) and oblige them. This happens relatively infrequently. Even if I peeled every apple that we ate, that would still only amount to a few peelings per day.

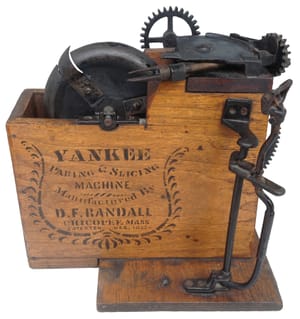

Apple peeling was apparently much more common in the eighteenth and nineteenth centuries, and from the ubiquity of the task arose countless solutions. I like to think of them as akin to a field of wildflowers, each attempting to advance its own strategy to a common problem. They – the apple parers – are described in a broad and intricate taxonomy in Don Thornton’s 1997 book, Apple Parers. The book is over two hundred pages long, and contains over five hundred and fifty photos and two hundred and fifteen patent drawings. It describes apple parers – manually-operated machines which quickly remove an apple’s skin and, in some cases, also core and slice them – as meaningful pieces of infrastructure to early American life, and as a category of tool for which “the competition was intense.”

Apple parers utilized quite varied design strategies over the years. Broadly speaking they can be divided up into lathes, turntables, returns, arcs, commercials, and primitives – though these terms overlap quite a bit, and you might think of them more as attributes than as distinct categories. Regardless, the design language on display in Apple Parers – and in the Virtual Apple Parer Museum – is nuanced, evolved, and colloquial. There are also copious references to “Yankee ingenuity,” a term that I find a little too earnest, but which I’m sure conveys something true about the entrepreneurial energy devoted to apple-peeling machines at the time.

And anyway, it’s delightful to read essays on specific antique parers which note the author's “weak knees” when first seeing the parer in question. Perhaps more striking are the words of appreciation for the community around apple parers; it’s evident that the International Society of Apple Parer Enthusiasts (nicknamed APES) provided many of these people with genuine, long-lasting social warmth. The foreword of Apple Parers spends much time describing these relationships, noting also that the writer shared an enthusiasm for apple parers with colleagues while working at Lockheed in the 1970s and 1980s. As Ben Rich describes it in Skunk Works, the Lockheed engineering culture at that time was confident, hardworking, and fast-moving; perhaps the iron gears of apple parers contained a relatable flavor of nineteenth-century techno-optimism.

Apple parers seem to show that for any particular problem – how to pare an apple, how to join two pieces of metal, how to produce baseload power to the electrical grid – there should be a nearly endless number of solutions. It is this fact that excites me most about browsing a hardware store or industrial supply catalog. If a tool comes in many varieties, that’s proof of a problem that many people have tried to solve before me. Selecting a tool, then, is an opportunity to see my problem from someone else’s vantage point.

What problems have I faced down this year? In the workshop, I have continued to do a ton of work on my bikes, a practice which justified a few tool purchases. The most exciting of these is a ridiculously nice spoke tensiometer, a tool which applies a load to the side of a tensioned spoke and measures how much the spoke deflects as a result. You can see it being used here; I find it rather awkward compared to my old tensiometer, but it’s nice to have a tool which is commensurate in precision with the objects I’m using it on (I keep my bikes’ wheels in very good condition, if I may say so myself).

But working on my bikes is in many ways more about my own sense of psychic order than it is about mechanical engineering; my home has probably been a more prominent source of true engineering problems this year. How interesting these are to you probably correlates highly with the age of your home. Mine is almost a century and a quarter old and at this point I anticipate putting at least a few weeks’ worth of Saturdays into its maintenance every year. I both relish and am deeply anxious about this work, and am intensely curious about the work that other people put into homes of a similar age.

My biggest recent accomplishment there was patching and repainting the drywall on our basement ceiling, which had been hacked apart due to a small termite infestation (they really are impressive creatures) and the installation of a new induction range in our kitchen above (which has been a total pleasure to use and which I recommend highly, even if you think that gas provides a superlative cooking experience). I was, to be honest, dreading this project. I have very little experience with spackle, and my final results were really only suitable for a basement, but it ended up being quite satisfying work and was a relaxing task to have on my list of things to do once the kids were asleep. It also provided a half hour of very messy and haphazard fun for my six-year-old one Saturday afternoon, and in retrospect I should have set her up with her own spackle knife and a piece of scrap sheetrock to play with much earlier in the project.

I have a few little projects on my list for the rest of the year, the biggest one being the couple of floorboards that need to be replaced due to the aforementioned termites. (Our floors are likely made of old growth longleaf pine – a material that showed up in my writing earlier this year, and which I plan on covering in more detail in the future.) But a larger project looms: Our house needs a stormwater storage system which is in many ways a miniature version of the municipal one that Hillary described in August. This will, I’m sure, occupy my thoughts for weeks, and will involve at least a few days’ worth of manual digging – things that I’m both worried and excited about.

Why my excitement? Partly because it's been years since I've had more than a few minutes with a shovel in my hands, a tool which I find dynamic, rhythmic, and wonderfully challenging to use for long periods of time. But partly it's because our house suffers from a set of problems that elude a single solution, and as a result I find myself cobbling together a series of tools to fix them. When I find myself anxious about this, I like to think that I'm standing in a field of wildflowers – and instead of picking just one, I get to assemble a whole bouquet.

Scope creep.

- The title of this piece is a reference to the 1956-57 Hundred Flowers Campaign, in which Mao Zedong invited intellectuals to submit criticisms of the Chinese Communist Party. Like most campaigns of the age, the Hundred Flowers Campaign did not end happily.

- An interesting piece by Michael Pollan about the apple’s role in early US culinary and agricultural history, and an essay on apple parers' role in the gender and labor history of the time.

- Carlo Rovelli published a new book about white holes, which are like black holes reversed in time: You can only leave them, and never enter them. I have so far listened to the audiobook three times (I’m pretty sure I’m over a dozen on his 2019 The Order of Time).

Happy Thanksgiving, and good luck with whatever you've got on your plate for the rest of 2023.

Thanks as always to Scope of Work’s Members and Supporters for making this newsletter possible. Thanks also to David Paskin for enthusiastically suggesting apple parers as a topic of interest, and to David Marchese for suggesting that the two of us speak about the topic in the first place.

Love, Spencer

p.s. - We care about inclusivity. Here’s what we’re doing about it.