In 2019 my Grandma passed away and I inherited a dusty collection of Lego bricks from her loft. At first these bricks looked just like those of my own childhood, but my hands and eyes are well trained from thirty years of play, and close inspection revealed tiny clues that suggested they came from a different era. I imagined myself as a plastic archeologist, scouring the surface of these bricks to analyze and interpret the society that left them behind.

Plastic is already making an unwelcome appearance in archeological digs across the world, and it seems inevitable that plastic archeology will one day become its own field. I’m curious how such a ubiquitous material will be used to tell the stories of our day. Plastic is lightweight and easily breaks down into small pieces; it can travel vast distances and is dispersed easily. Far removed from their original context, the plastic artifacts of tomorrow are unlikely to be analyzed using the same methods that archeologists apply to stone tools today.

Instead, it may be that ideas borrowed from reverse engineering will help unlock insights about the plastic of our time. Mixing engineering with archeology has helped me peer deeper into the history of my grandmother’s bricks, and I invite you to consider how ideas drawn across disciplines can help to understand the origins of the objects that surround us.

Only cement and steel are manufactured more widely than plastic, and 22% of plastic evades waste management systems, ending up in uncontrolled dumpsites or lost directly into the environment. This has given rise to the idea of the plasticene era, a sub-stage of the anthropocene in which plastic is buried as sedimentary material and combines with minerals to form new rocks. One example of these new plastic-mineral compositions is plastiglomerate: sedimentary granules and debris held together by plastic, such as those found on a remote Brazilian island.

To see plastic so deeply embedded in the fabric of our world is unnerving. Yet from an archeological perspective I’m struck by the way that plastic objects now lie on the cusp between trash and treasure. The boundary is ill-defined, but historic preservation laws provide a good starting point. In the United States, any digging using federal or state money must have an archeological assessment to evaluate items found that are older than 50 years. Objects made of plastic now straddle this divide: Are they environmental blights that need removing and recycling, or curious finds to be studied and classified?

This trash-treasure divide has been explored by others before, such as these UNC archeologists who presented waste items as archeological finds. But my favorite plastic archeologist is Tracey Williams. Since 1997 she’s been hunting and cataloging the washed-up Lego from a shipping container that fell into the sea. Lego provided a detailed inventory of the container’s contents, which has resulted in much speculation about why some parts wash up, and whether others will perish on the seabed, never to be found. That said, deep underwater the low temperatures, higher pressures and reduced photodegradation in low light are thought to have a preserving effect. The discovery of Atari game cartridges in a landfill site, perfectly playable 30 years later, showed that materials in sheltered environments can survive for surprisingly long times. Perhaps the remaining Lego bricks will one day be discovered too.

My own investigations into my grandmother’s bricks began with the traces of their manufacturing processes. The scars of injection molding are obvious once you start looking, such as the gate from the tip of the hot runner, or flow leaders to accelerate molten plastic into the corners and ensure consistent shrinkage during production.

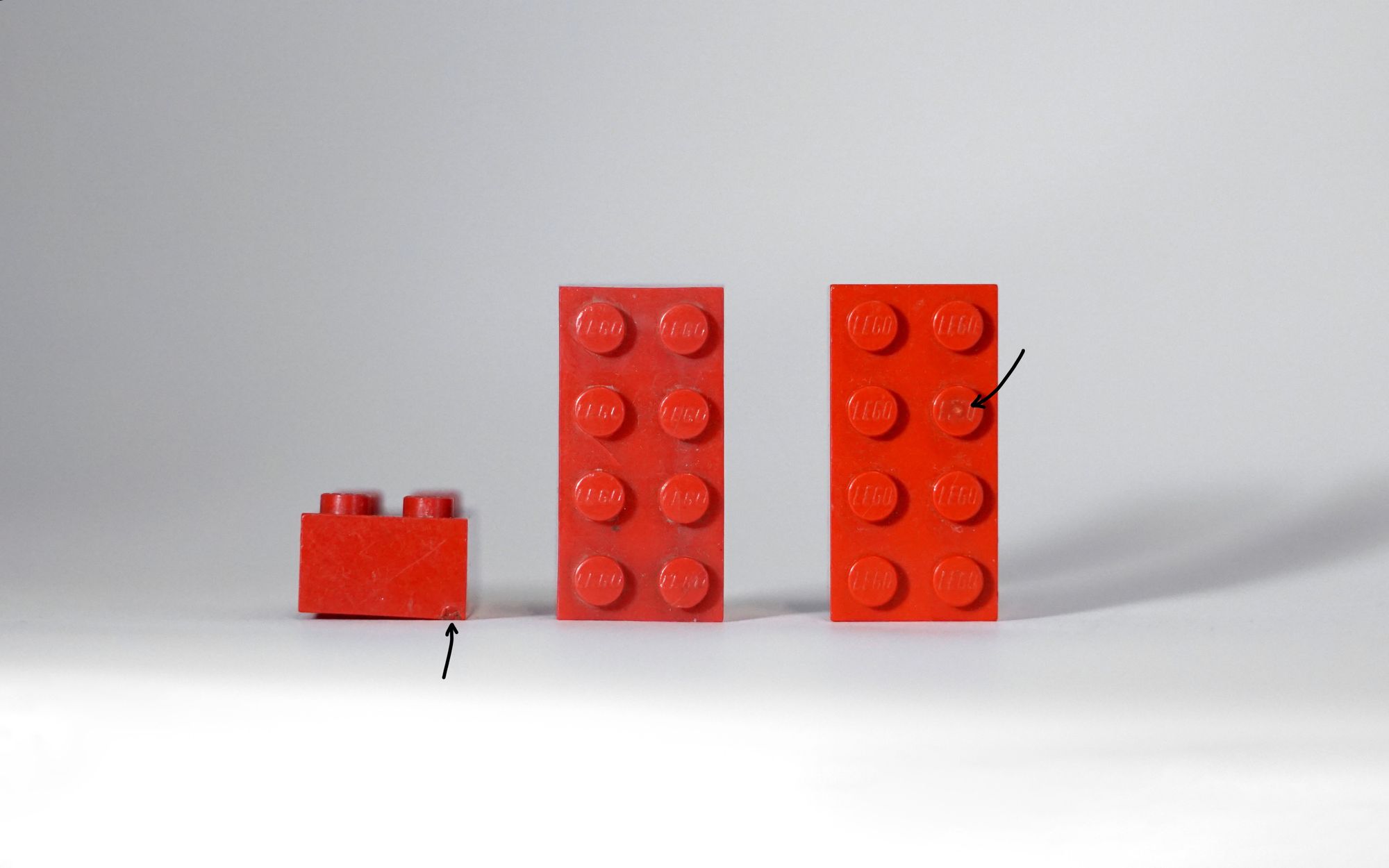

In contrast to the shape of the brick itself, which has changed little since the late 1950s, engineers at Lego are constantly improving the bricks’ manufacturing features. Some of my grandmother’s early bricks have a small blemish on the lower edge, the telltale sign that Lego engineers once favored tab gates over hot runners to inject plastic into the mold. Distinctions like this one are cataloged by a passionate Flickr community who specialize in Lego part number 3001, the 2x4 brick. I was able to date some of my grandmother’s bricks to around 1958 based on the font of the Lego wordmark embedded in every stud, and by the tiny molded numbers on their undersides, which identify the part’s mold cavity.

The 2x4 brick is sometimes referred to as the Rory, for reasons I’ve been unable to fully ascertain. The design of the interference fit for joining these bricks together with holes and grooves is captured in the original 1958 patent filing. This durable, tightly toleranced fit is the reason Lego models stay standing, and some bricks can tolerate over 37,000 assembly cycles before failing. The most fascinating part of the patent for me is figures 9-11, which illustrate a set of curious interlocking designs that were never mass produced but can be seen today in a test part from the injection mold at the Lego Museum in Billund, Denmark.

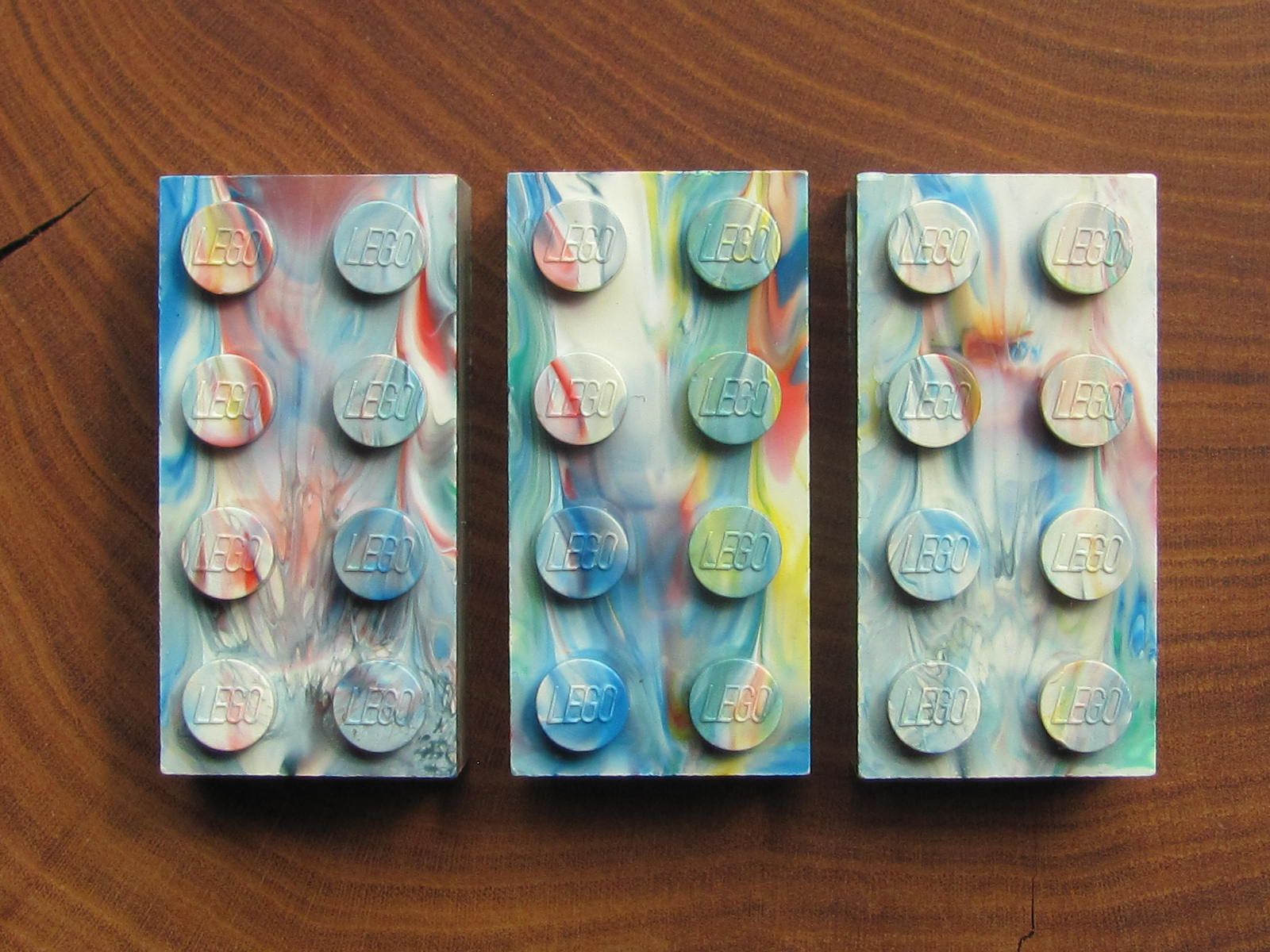

While Lego bricks made today are reverse compatible with ones made in the late 1950s, they do differ in one significant way: the material they’re made from. Many of the bricks I found in my grandmother’s loft were noticeably warped and had an unusually shiny surface, signs that they’re likely to be made from cellulose acetate (CA). CA was an early natural plastic, created by French chemist Paul Schützenberger in 1865 by reacting acetic anhydride with the natural cellulose polymer derived from wood pulp. After CA's lack of rigidity proved problematic, Lego hired Swiss plastics expert Hans Schiess in 1961 to explore alternatives. German plastic suppliers Bayer and BASF produced test bricks in a variety of materials and colors, many of which are highly sought after by collectors today. The chosen replacement was acrylonitrile-butadiene-styrene (ABS), whose superior dimensional stability to CA is a big reason why early ABS bricks will still mesh securely with those molded today.

As a graduate engineer, I have a formative memory of asking an older colleague for help in identifying the grade of plastic of a sample I was holding. He took it from me and smiled before tapping it against his teeth and listening intently to the sound.

I was never clear if this was science or theater, but different plastics do have distinctive physical properties which can be felt, smelt or heard. CA, for instance, deteriorates after exposure to acids or heat, giving off acetic acid and lending the term ‘vinegar syndrome’ to the breakdown of film stock. Archeologist Mari Isa tells the story of finding a suspected Bakelite (another early plastic) artifact in a dump and trying to identify what it was made of. “People who have handled a lot of Bakelite can make an assessment based on subtle clues like sound and feel. Since I have not handled much of it myself, I turned to some of the other ‘tests’ for Bakelite.”

These other ‘tests’ are often quite destructive. Working as a design engineer I would sometimes refer to Stanmech’s Plastics Identification Flowchart, which advises burning a small sample and observing the color, odor and speed of burning. In the interests of science archeology I subjected a set of my own bricks and my grandmother’s to these tests. Both burned with a yellow flame which did not self-extinguish, producing black smoke and soot. But the modern bricks burned cleanly with a bitter rubber smell, whilst my grandmother’s sparked with a discernible smell of vinegar – confirming once and for all that they were indeed the vintage CA bricks I had first suspected.

Before I inherited these bricks I would never have considered myself an archeologist. However, approaching this act of reverse engineering through the lens of archeology has encouraged me to look beyond the function of the Lego bricks and consider the context in which they were created, and the reasons they’ve survived to this day. Our creations never exist in isolation from the world, and the marks left behind on their surface will tell our story once we’re gone. I’m excited to bring more of this archeological mindset to my future work.

SCOPE CREEP.

In writing this I found myself on many tangents into the world of design fiction, trying to imagine what a plastic archeologist of the future might get up to. Often referred to as archeology for the future, design fiction is a creative technique that uses fictional prototypes of everyday, mundane objects to tell stories about the future. I find the way it eschews glossy concept videos to focus on the mundane detritus of our world a refreshing approach to future gazing.

Thanks as always to Scope of Work’s Members and Supporters for making this newsletter possible. Thanks also to Xavier and Laura for their contributions, and of course to Erinna and Lukas, who remind me every day to take my pleasure seriously.

Love, George

p.s. - If you know of any design fiction involving drones, just reply to this email – I’d love to hear about it.

p.p.s. - We care about inclusivity. Here’s what we’re doing about it.

When this piece was first published, we mistakenly said that cellulose acetate was used for projector film. Projector film was actually made of cellulose nitrate; the text has since been corrected.