A deep dive into the complicated controls inside commercial aircraft.

When boarding a commercial flight, passengers often get the chance to peer into an open flight deck to see the pilots running through pre-flight checklists. The flight deck (more commonly known as the cockpit) is about as cramped as a typical walk-in closet. Inside this tiny control room are two pilot seats, one or more jump seats, and short walkways much narrower than the aisles in the passenger cabin. Within arm’s reach of each pilot is a dazzling array of switches, levers, buttons, and screens – hundreds of user interface elements, packed tightly together with only the tiniest of labels.

Within the field of human-machine interfaces, flight decks present unique constraints. Flight deck design sits at the intersection of aerospace engineering and human factors – the control panels that pilots use to fly airplanes serve as the user interfaces to many backend systems. Commercial airplanes are very complex machines, yet their control systems are designed such that a single human can maneuver the aircraft in three axes, communicate with air traffic controllers, and more.

History of Flight Decks into the Digital Age

Modern flight decks might look packed with physical controls, but they used to be way more complicated. Prior to the advent of fly-by-wire in the 1970s, flight decks were stuffed with dials, circuit breakers, and mechanical levers. Old commercial flight decks, such as those onboard the Concorde and the original 747, contained walls filled with instruments that had to be constantly monitored to gain live status of aircraft systems – a heavy cognitive burden for the flight crew. Analog dials surrounded the three-person crew: two pilots and a flight engineer, whose role was to help pilots manage the torrent of information in the flight deck. Though meticulously laid out, all of these instruments, analog gauges, and controls competed for space and attention.

The paradigm of electronic flight decks revolutionized aviation. Fly-by-wire (and subsequently, the glass cockpit, a term that refers to the use of digital displays) shifted complexity from user interfaces to their backend avionics. They also revolutionized flight deck design, forcing engineers to think critically about how and when information should be presented to pilots. Digital displays replaced analog gauges, and physically controlling the airplane through cables and pushrods was replaced by simulated feedback generated via electronic signal processing. As flight software became ubiquitous and flight deck interfaces simplified, the role of the flight engineer was no longer needed, reducing the minimum required crew to two pilots. Launching into the digital age, the introduction of autoflight systems further reduced pilot cognitive workload so that pilots could save their energy for more active phases of flight – namely takeoff and landing.

Backend Automation vs. Human Input

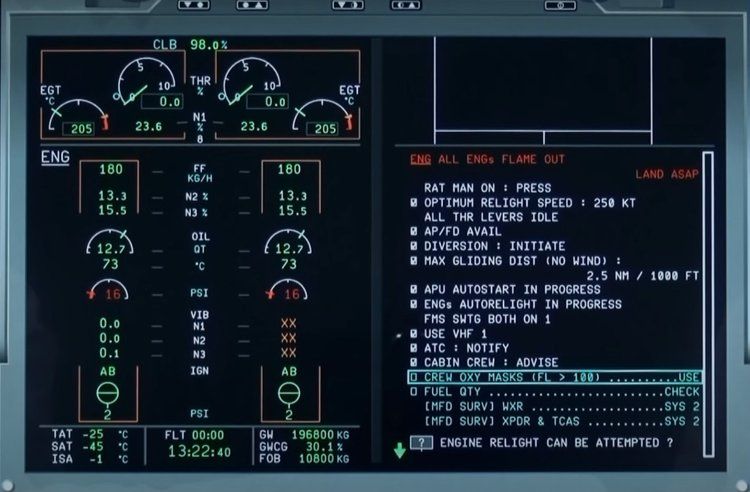

In recent decades, the ever-growing presence of automation and backend flight software made air travel safer by offloading flight tasks from human pilots to backend computers. In commercial jets, many flight instruments were replaced with electronic systems such as the Engine Indicating and Crew Alerting System (EICAS; see Bombardier’s EICAS control panel & usage instructions here), which uses standardized colors and sounds to provide alerts in order of urgency. Modern alerting systems even display emergency checklists to help pilots systematically think their way through non-normal situations such as an engine fire or bird strike.

In ideal conditions, modern airplanes can pretty much fly themselves. However, accidents involving automation such as Asiana Flight 214 and Air France Flight 447 have made the FAA and the flying public still wary. Should potentially catastrophic hazards arise, the reality is that the airplane alone cannot handle the nuances of every emergency situation in the same way a human pilot might. Even with years of advancements in autoflight technologies, FAA regulations still specify that the pilot is the final authority as to the operation of the aircraft.

Flight deck engineers must test for a wide variety of emergency use cases to make careful tradeoffs between autoflight and human intervention, with the ultimate goal being safety. Too much reliance on automation runs the risk of creating widespread pilot automation dependence, called the automation paradox, which in turn risks diminishing pilot flight skills in potentially catastrophic scenarios. If pilots need to disable automation, they must understand how to manually operate the plane using the switches, levers, and buttons before them.

The Human Element

Implicit in flight deck design is accounting for human factors, such as fatigue and cognitive overload, that may hinder decision making in emergency situations. In fact, human factors emerged as a discipline during World War II in the 1940s, driven by cockpit design issues that led to a high rate of airplane crashes. It became increasingly well-known that equipment had to be designed with their users in mind, with repeated usability testing both at a component and a holistic flight deck level.

In the design of safety-critical human-in-the-loop systems, the human is the biggest source of uncertainty, yet somewhat ironically must be given the final authority. Therefore, there are many aspects to human cognition that must be considered in flight deck design. Haptic feedback and tactility both play key roles in helping pilots develop muscle memory, which is a major reason why flight decks are still full of physical controls. In many cases, pilots can access crucial controls without looking due to consistent locations and differentiated inputs, building a mental model of control locations inside pilots’ brains. Recurrent pilot training of both routine and emergency procedures reinforce these mental models.

Redundancy

Another reason why flight deck controls look complicated is redundancy. In fail-safe systems design, regulations dictate that multiple layers of redundancy are built in at a holistic level to lower the likelihood of a fatal accident. Redundancy is also built into the human machine interfaces: if the autopilot were to behave erratically or one of the flight displays were to lose power, pilots have secondary means of performing the same tasks. It is for this same reason that commercial airplanes still require two-person flight crews, with controls duplicated for each pilot workstation.

Of course, airplanes are not the only machines whose interfaces underwent a big shift in the digital age. In the automobile industry, Tesla famously reduced physical controls in their car dashboards to a mostly touchscreen user interface. Many cell phone manufacturers are expected to completely eliminate buttons in the coming years. Many smart home devices – thermostats, robot vacuums, TVs – can be controlled entirely by voice.

By contrast, the evolution of flight decks is conservative. For one thing, commercial airplane design cycles are significantly longer than those of mass consumer products; early design decisions can be outdated when a new airplane finally flies. But this slow rate of design evolution is part of a broader picture: commercial airplanes are designed to fly for about 30 years, roughly 3x than the lifespan for automobiles and 15x the lifespan of a cell phone. A pilot might run through the same routine checklists (Prepare the cabin for landing – announced. Speedbrake – armed. Landing gear – down. Flaps – set for landing.) every working day for decades, a process that produces rich mental models of flight decks and flight procedures.

In the design of Human Machine Interfaces, simplicity is relative to the end users and the product’s use cases, and flight decks are a classic example of interfaces built for experts in life-threatening situations. Pilots are highly trained to fly airplanes, and they receive extensive training and repeated opportunities to solidify their mental model of the layout – a layout that is rich in history and well-supported by aviation’s proven safety record. Maybe in the future, automation will have a much larger authority, enabling commercial flight deck interfaces to simplify even more. But for now, human pilots, and all the controls they need to fly airplanes, are here to stay.