The mortar and pestle is one of the most common kitchen tools in the world, and one of the most taxing to use. Why hasn't it been automated?

I hope, eventually, to remedy my shortcomings as a Singaporean cook, but there is one I know I’m never going to fix: I’m awful with a mortar and pestle. I know this because I use a food processor for my rempah-rempah – the spice pastes that provide the foundation for nearly every dish from maritime Southeast Asia. Rempah-rempah are traditionally made in a mortar and pestle (a lesung in Malay), and it’s proverbial that a good cook should be expert with a pestle. There’s a piece of folklore, repeated from Thailand to Timor, about matriarchs judging potential brides based on nothing more than the sound of their pestle-work.

Of course, most cooks these days use food processors to make rempah, a fact that inspires considerable angst. Much of this angst can be attributed to a certain romantic valorization of handwork over machinery, but there’s also a deeply ingrained idea, repeated as gospel and similarly difficult to verify, that the chopping action of a food processor and the crushing action of a lesung produce fundamentally different culinary results.

In other words, a generation of cooks relies on a piece of equipment they consider subpar - the food processor - because the market has not seen fit to provide a better solution. This situation encapsulates the complicated ways in which technology incarnates economic history, and the cultural burling that results.

The history of the food processor makes this seem like nothing more than the accidental result of first mover advantage. The food processor happens to have been invented first, and won wide acceptance before an automated mortar and pestle came along.

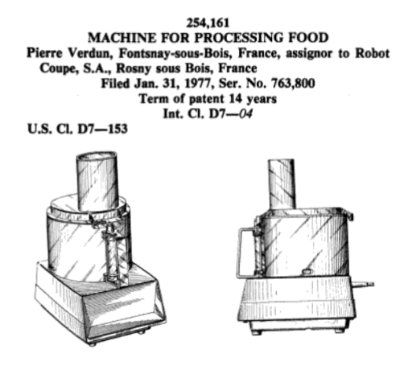

This history begins in the 1950s, with one Pierre Verdun, a salesman whose clientele were caterers and restaurants; what he sold them is hard to determine. The enterprising M. Verdun – for these characters are always enterprising – noticed that his customers spent a great deal of time chopping and slicing food. Or rather, he noticed that they paid a great many people to chop and slice, and so he set out to find a technological means of reducing their workload (or wage bill), launching the Robot-Coupe in 1960 (he seems to have first filed for a patent almost a decade before). Not long after, seeking to expand the market for his machine, he domesticated its industrial proportions and launched Le Magi-Mix, a petite version for the home.

An American businessman named Carl Sontheimer saw the Magi-Mix (or the Robot-Coupe; sources disagree) and decided that he could sell every housewife in America something similar. He licensed Verdun’s design and introduced it to America as the Cuisinart food processor, the essential design of which remains unchanged almost half a century later. Sontheimer’s genius was not in engineering but in marketing. He sent Julia Child a Cuisinart, which she liked so much that she carried it with her when she traveled (some sources suggest she actually had an early Robot-Coupe, either before or in addition). He sent another to Chuck Williams, who was trying to grow a new business called Williams Sonoma. Sontheimer’s efforts enabled the chain reaction of mass demand and mass production to take hold, and now the food processor is used all over the world.

This fits the popular idea of how innovation is supposed to work. Innovation is supposed to flow into every empty market niche, to find unmet needs and fill them, like so much grout smeared across the surface of our civilization.

If this mental model of innovation is accurate, we should expect the grout to flow relatively evenly across the cracks – if anything, it should flow most easily into the largest cracks, with the largest markets being addressed most quickly (given the limits of science and technology).

The mortar and pestle is among the most widely used kitchen tools in human history. I’m most familiar with its uses in the Southeast Asian kitchen, but it was, and often still is used daily, by large swaths of the population everywhere outside Europe. The tasks for which the mortar and pestle is used are no less time consuming and physically tiring than the cutting and shredding that Verdun sought to automate. The potential for mechanization here is obvious, but somehow, innovation hasn’t yielded an automated mortar and pestle for the kitchen.

This particular niche was probably never filled because it was never seen as a niche that needed filling. The mortar and pestle have never really been as central in European kitchens as they have in kitchens outside Europe, and the people laboring over them for hours a day were almost inevitably women of color - the colonized rather than the colonizers.

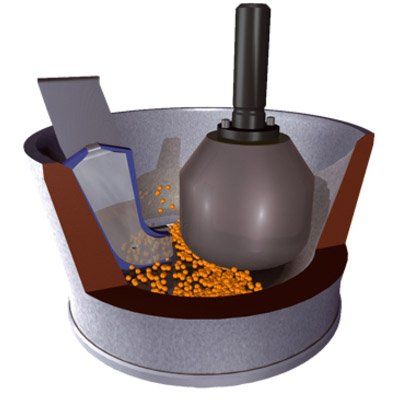

Instead, the grout somehow flowed into a much smaller gap. In 1923, F. Kurt Retsch launched a piece of scientific equipment he called the Retschmill (or generically, a mortar grinder), designed to replace the “tiresome manual grinding with hand mortars which was the standard in laboratories.” In other words, Retsch was trying to replace the labor of (mostly white, mostly male) commercial users familiar to European machinery manufacturers.

The market first supplied a solution with a total addressable market consisting of a few tens of thousands of laboratories worldwide, rather than for the hundreds of millions of households across India and Southeast Asia – and that’s before counting the households in Africa, South and Central America, and the Middle East. It’s even more telling that in the (admittedly eventful) decades between the introduction of the Retschmill and the introduction of the Robot-Coupe, nobody seems to have thought to domesticize the mortar grinder.

I wanted to see if it would be feasible to use a mortar grinder in the kitchen, but the cheapest mortar grinder I could find was more than $2000 new – far more than most people would pay for a kitchen appliance. Even if you bought it for your kitchen (the way anyone interested in sous vide cooking before 2010 or so would have had to buy a $990 Polyscience circulator), the action of these lab machines is more like the grinding action of a quern stone than the pounding action used for most of the food preparation that takes place in a mortar. It’s not wholly inappropriate for culinary uses (in some parts of the Malay archipelago, pastes are prepared using a quern-like action in a batu giling, as they are in parts of India and Central America), but it’s not quite the same as the reciprocating movement you see cooks use with a mortar and pestle.

Consumer technologies succeed not solely on the basis of their efficacy, but also because they fit, or embody, particular sets of social and cultural mores (as numerous attempts to introduce the Toyota Production System illustrate). The food processor leapt from the catering kitchen to the home partly because Sontheimer and Verdun were following the capitalist imperative for continual expansion, and home kitchens outnumber professional ones by an order of magnitude. But the fact that they succeeded in expanding their market points to a societal acceptance, or decision, that this approach to production was appropriate. America and Europe decided that homemakers – not just caterers – should have the ability to grate a sack of carrots in 10 minutes.

That decision - and all the decisions made in the long shadow of colonialism - has ended up acting as a trojan horse for further westernization. The foodways of the Malay archipelago are not only a major source of pride, they’re also tightly bound up with communal practices that are quickly eroding. A device that not only makes preparing food a less communal activity (because it increases a single person’s productivity), but does so by preparing the food improperly (because it cuts rather than crushing), is a complicated proposition.

So the angst about the increasing use of food processors for tasks traditionally accomplished with a lesung isn’t just reactionary luddism. It’s also about the sense that we’ve imported a solution to modernity that certainly wasn’t designed for us, and might have been imposed on us. The same modernity that atomizes and hurries our lives, eliminating the space in which a slow, communitarian cuisine could breathe, has delivered a solution for making the same food more quickly. The food processor is both a countertop appliance and a tiny, quotidian reminder of how, in Asia, the narratives of economic development, modernization, and westernization lie together like strands in a hawser.