I recently read two descriptions of very different manufacturing processes. The first was about steelmaking in the late 18th century in the always excellent Construction Physics:

In the puddling process, pig iron would be placed in a coal-fired reverberatory furnace, which separated the fuel from the iron by a low wall. Ironworkers (called puddlers) would constantly stir the pig iron to expose it to oxygen, and the flow of air over the iron would decarburize it (emphasis added).

The other, from the Brookings Institution, was one of the most moving paragraphs I read last year:

An extreme ultraviolet lithography machine is a technological marvel. A generator ejects 50,000 tiny droplets of molten tin per second. A high-powered laser blasts each droplet twice. The first shapes the tiny tin, so the second can vaporize it into plasma. The plasma emits extreme ultraviolet (EUV) radiation that is focused into a beam and bounced through a series of mirrors. The mirrors are so smooth that if expanded to the size of Germany they would not have a bump higher than a millimeter. Finally, the EUV beam hits a silicon wafer—itself a marvel of materials science—with a precision equivalent to shooting an arrow from Earth to hit an apple placed on the moon. This allows the EUV machine to draw transistors into the wafer with features measuring only five nanometers—approximately the length your fingernail grows in five seconds.

In the 250 years since puddling was first invented, we’ve developed industrial processes, like EUV lithography, that are almost indistinguishable from magic. However, there are still workers who stir molten metal by hand today (albeit with more protective equipment). Whether a steel foundry looks magnificent or hellish probably depends on whether you’re viewing it from the floor or somewhere far away.

It’s often been argued that manufacturing’s decline in richer nations is due to a PR problem. And while that might be a factor, there’s a much more intractable issue: making physical things is still often dirty, dangerous, demeaning, or some combination of all three (and unfortunately, our social paradigm often makes these add up to a fourth D – disposable). Salaries can be raised in minutes, PR campaigns can be waged in months, but this reality is much harder – or simply less economical – to change.

That description of semiconductor manufacturing would be a great addition to a PR campaign for manufacturing careers, but it describes a tiny sliver of the sector. If semiconductor manufacturing is a gleaming spire, primary industries like steelmaking and agriculture are its unglamorous but irreplaceable foundation. How do we make employment in these subsectors as safe, remunerative, and prestigious as working in a chip foundry?

The most clicked link from last week's issue (~9% of opens) was a call for participation in a study about drying laundry. In the Members' Slack, we've been thinking up a list of the "fundamental machines of industrial civilization" and swapping recommendations for rolling luggage for little kids.

JOBS.

- Terraline is hiring a senior battery engineer in Fremont, CA.

- Eventide Inc. is hiring a purchasing manager in Little Ferry, NJ.

- First Resonance is hiring a manufacturing solutions engineer in LA.

- Nautilus Defense is hiring a lead electrical engineer in Pawtucket, RI.

- Partnership for New York City is hiring a manager for the Transit Tech Lab in NYC.

- More jobs on Scope of Work's job board; you can promote the role you're hiring for here.

SPONSORED.

Graphene is very difficult to manufacture at any scale, but Ora Graphene Audio believes it’s cracked the code with the development of a proprietary nanomaterial known as GrapheneQ. Check out how the company makes premium headphones using proprietary graphene membranes with Fusion 360 at the heart of its design process.

PLANNING & STRATEGY.

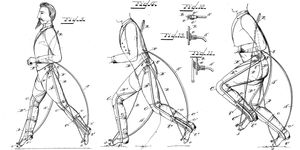

The relative frailty of the human body makes work-related musculoskeletal disorders (WMSDs) – a category that includes repetitive strain injuries and other painful disorders like tendonitis – one of the most significant and insidious safety issues facing manufacturing workers today. Exoskeletons for industrial use are often touted as an ideal solution, but like self-driving cars, they’ve been “just over the horizon” for years.

There has been some adoption, but instead of set ups akin to Ripley's power loader from Aliens, companies are strapping molded plastic and springs to workers. As this meta-study on exoskeletons explains, “they tend to show more of their potential in static activities, while in dynamic tasks, they can [be an] obstacle [to] regular job performance.” This means most of the gains are afforded by passive systems that rely on mechanical means to relieve strain without actuators or electronic components.

On the one hand, this means that low cost solutions like this arm support for construction are a promising and cost-effective route for reducing strain injuries. On the other, calling these “exoskeletons” sets up a major expectation gap, which probably does little to improve the image of manufacturing work.

MAKING & MANUFACTURING.

One example of this expectation gap is fried rice. As this paper describing the physics of fried rice notes, any process that requires stressful, repetitive motion, like tossing fried rice in a wok dozens of times a day, is a good candidate for an assistive exoskeleton. The activity is provably harmful to the human body and takes place mostly (but as the paper shows, not entirely) on a single plane – and so the authors hope their “study may inspire the design of stir-fry robotics and exoskeletons to reduce the rate of muscle strain injury among professional chefs.” In practice, though, even before you factor in the nimbleness and range of motion required by high-speed line cooking, this is precisely the sort of dynamic task in which exoskeletons are more hindrance than help.

Our best attempt so far at solving the fried rice problem seems to be replacing the human rather than augmenting them. The paper cites this fried rice making robot, but notes that its performance doesn’t come close to what an expert wok-user can achieve. It turns out that it’s hard to improve upon self-propelled, fully autonomous machines with dozens of degrees of freedom – human bodies.

So the question of how to safely make fried rice encapsulates the challenge for manufacturing: If we want to make the field more attractive by eliminating some of the Ds, our options seem to be to augment the human body, replace it, or design processes to accommodate it – and even with the technology at our disposal, the first two options seem to have proven elusive.

MAINTENANCE, REPAIR & OPERATIONS.

Writing about exoskeletons reminded me of the idea that infrastructure has made us all cyborgs already (which I came across in this beautiful piece by Deb Chachra, which also considers Ellen Ripley’s power loader).

Alone in my apartment, at dusk, I flip a switch to turn on a light. In that instant, not only are my individual senses augmented (now I can see at night), but I become part of a continent-spanning colossus. My reach extends out for thousands of miles, across a national border, encompassing a nuclear power plant, a massive hydroelectric project, scores of substations, thousands of pylons, and an incalculable amount of human expertise, skill, and labour.

If infrastructure is an extension of the body, then surely a workplace is an extension of the worker as well. Work environments could be designed to eliminate strain altogether – making the workplace a distributed cyborg system. One could read the Occupational Safety and Health act as mandating this approach, by directing that employers must try to design safe workplaces, relying on personal protective equipment only as a last line of defense (I am not a lawyer, and I’d love to hear your take on this if you are a lawyer).

We’ve gotten pretty good at building gantry systems that move cars in 6 axes of motion, so we could clearly design car assembly lines that eliminate overhead work and its toll on workers’ bodies. However, automobile assembly plants are one of the main markets for strain-reducing passive exoskeletons, because overhead work remains commonplace. Companies have seemingly decided that it’s more efficient to equip autoworkers with passive exoskeletons to “reduce strain” rather than aiming for “no strain.”

I think there’s a line in the popular imagination that divides “tools” from “sci-fi cyborg shit,” and screwdrivers and exoskeletons fall on different sides of that line. But if infrastructure systems and workplaces make us cyborgs, arguably tools do too. Exhibit A: the automatic rebar tier. The rebar skeleton in a reinforced concrete structure needs to be lashed together with, essentially, giant twist ties. This literally used to be done with nothing but a hook, causing extremely high rates of repetitive stress injuries in concrete workers’ hands and wrists. The automatic rebar tier replaced this twisting action with the pull of a trigger and now there are long reach versions that eliminate even the need to crouch. Both automatic rebar tiers and passive exoskeletons provably reduce the rates of WMSDs.

DISTRIBUTION & LOGISTICS.

- This Bureau of Labor Statistics study found that transport and logistics was the sector with the highest rate of WMSDs in 2018 (the second chart can be toggled to show this).

- To return to the question of augmenting, replacing, or accommodating humans: if we replace the human body, how do we deal with the social implications of large scale replacement of humans in the value chain? Or, as Hillary asked me, “is it better to have a dangerous job or no job?” Amazon seems to be doing its best to run a real-world experiment on this subject, deploying increasingly sophisticated warehouse robots. However, the company makes a good case that replacing humans in the most strenuous and dangerous jobs doesn’t necessarily mean reducing the number of humans in the workplace – in the last 10 years, Amazon added half a million robots to warehouse floors and over a million humans.

INSPECTION, TESTING & ANALYSIS.

This 20-year old pamphlet illustrates some simple (and cheap!) ways to improve ergonomics on farms. At the time, the assumption seems to have been that all these solutions would be home-brewed on the farm after a quick trip to Home Depot. When I tried a quick google search today, there are commercial versions of most of the equipment available, like this harvest cart, that seem much fancier than what the pamphlet envisioned.

I tried to find data on the incidence of WMSDs in agriculture over time, to see if the recommendations from 2001 had any effect, but studies have been few and far between, and in the US, at least, government surveillance of the issue is virtually non-existent. Perhaps more inspection and enforcement would help, since the study found “emerging data suggest that agriculture faces a near epidemic of musculoskeletal disorders” – and that “these potentially permanently disabling injuries are readily prevented using ergonomics approaches.”

One uniting factor in all these situations – from car factories to Chinese restaurant kitchens to the cilantro fields of California – is economic pressure. The simple fact is that global labor arbitrage has made it cheaper to replace lost manufacturing labor (whether it’s lost to injury or withdrawal from the labor market) than to invest in the systems needed to make farms and factories more attractive workplaces.

SCOPE CREEP.

This amazing piece about the technology of automotive paints is where I first saw the car conveying gantry systems mentioned above.

Thanks as always to Scope of Work’s Members for supporting Scope of Work. Thanks also to Ed on the Member’s slack for the post that inspired this issue, and Sarah for all the links!

Love, tw

p.s. - We care about inclusivity. Here’s what we’re doing about it.